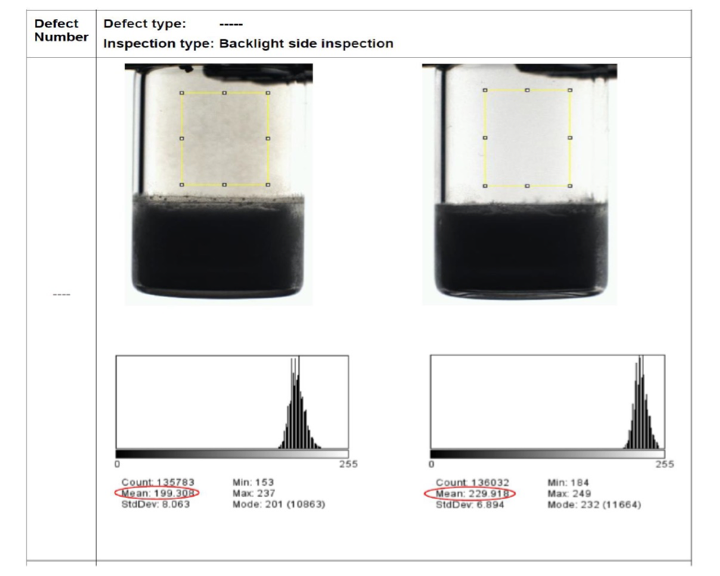

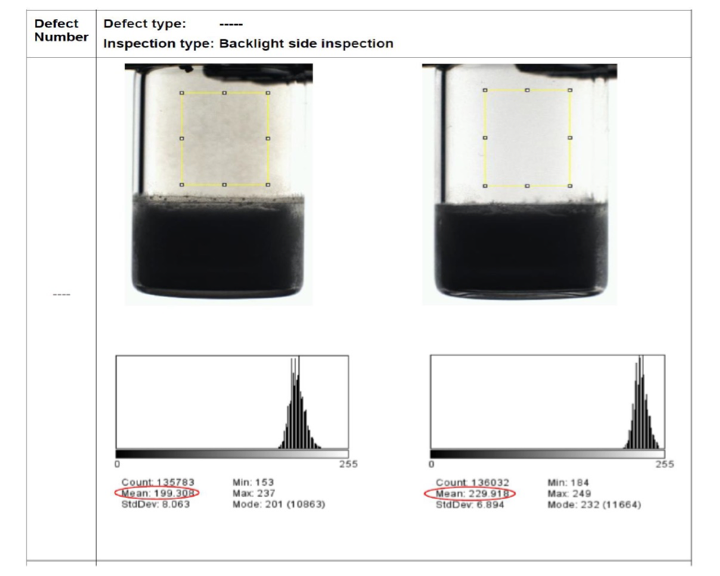

Addressing Defects In Lyophilized Vials Through Advanced Automated Inspection

Table of Contents

Types of Defects Detected in Lyophilized Vials

Lyophilized vial inspection must identify a range of defects impacting product quality and patient safety. These defects can be broadly categorized into visual defects and content defects. Container Closure Integrity (CCI) testing is also critical.

Visual Defects

Visual imperfections significantly impact the aesthetic appeal and can hint at underlying quality issues. Common visual defects include:

- Cracks: Microscopic cracks in the vial glass can compromise sterility and lead to leakage. Automated systems using high-resolution cameras easily identify these minute fractures.

- Particulate Matter: Foreign particles visible within or on the vial can indicate contamination during the manufacturing process. Image analysis software integrated into automated systems quickly flags these particles.

- Discoloration: Changes in vial color can signal degradation of the product or the vial itself. Advanced systems employ spectral analysis to detect subtle color variations.

- Vial Damage: This includes chips, scratches, or deformations on the vial's surface which can compromise integrity and sterility. High-resolution cameras and sophisticated algorithms are crucial in detecting such damage.

These defects, if undetected, can lead to product recalls, regulatory non-compliance (e.g., FDA cGMP violations), and potential harm to patients. Automated systems utilizing advanced image processing and machine learning algorithms significantly improve the detection rate of these visual imperfections.

Content Defects

Defects within the lyophilized cake itself are equally crucial to detect. These include:

- Insufficient Fill: An insufficient amount of lyophilized product reduces the dosage efficacy and can be detected through weight sensors integrated into automated systems.

- Cake Collapse: A collapsed cake indicates potential degradation or damage during the freeze-drying process. Automated systems can use optical analysis to detect variations in cake morphology.

- Foreign Particles within the Lyophilized Cake: Sub-visible particles within the cake are difficult to detect manually but can be identified using technologies such as near-infrared (NIR) spectroscopy or Raman spectroscopy. These techniques are increasingly integrated into automated inspection systems.

These content-related defects directly impact drug efficacy and patient safety, making their detection paramount.

Container Closure Integrity (CCI) Testing

Maintaining container closure integrity (CCI) is critical to prevent contamination and maintain product sterility. Automated systems enhance CCI testing through various methods:

- Vacuum Decay: Detects leaks by measuring pressure changes within the vial over time. Automated systems significantly improve the speed and accuracy of this process.

- Dye Ingress: A dye solution is applied to the vial's exterior; leaks allow dye penetration which is detected using automated visual inspection.

- Headspace Gas Analysis: Analyzes the gas composition within the vial headspace to detect leaks. Automated systems can effectively monitor and analyze gas changes.

Automated CCI testing significantly increases the accuracy and throughput compared to manual methods, ensuring that only vials maintaining integrity are released.

Benefits of Automated Inspection for Lyophilized Vials

Automated inspection offers significant advantages over manual inspection methods for lyophilized vials.

Enhanced Accuracy and Efficiency

Automated systems drastically improve the speed and accuracy of defect detection:

- Increased Throughput: Automated systems can inspect hundreds or thousands of vials per hour, exceeding the capabilities of manual inspection.

- Reduced Human Error: Automated systems eliminate human fatigue and subjective judgment, leading to significantly fewer false positives and negatives.

- Lower Labor Costs: Automation reduces the need for large teams of human inspectors, resulting in significant cost savings.

- 24/7 Operation: Automated systems can operate continuously, increasing overall productivity.

Improved Data Management and Traceability

Automated systems provide comprehensive data management and traceability, which is crucial for regulatory compliance:

- Data Logging: Detailed records of each vial inspected, including images of detected defects and inspection parameters.

- Reporting Capabilities: Automated generation of reports for quality control and regulatory compliance purposes.

- Integration with other Quality Control Systems: Seamless integration with existing enterprise resource planning (ERP) and quality management systems (QMS) enhances overall data management and traceability. This facilitates compliance with regulations like FDA 21 CFR Part 11.

Reduced Risk of Contamination

Automated systems minimize the risk of contamination, a critical factor in sterile pharmaceutical production:

- Closed-System Inspection: Many automated systems operate in a closed environment, reducing the risk of human-introduced contamination.

- Minimized Human Interaction: Reduced manual handling during the inspection process significantly reduces the risk of cross-contamination.

Choosing the Right Automated Inspection System

Selecting the appropriate automated inspection system requires careful consideration of several factors:

Factors to Consider

- Throughput Requirements: The desired inspection speed directly impacts the system's capacity.

- Types of Defects to be Detected: The system must be capable of detecting the specific defects relevant to your product.

- Budget: Automated inspection systems vary in cost; selecting a system within your budget is crucial.

- Regulatory Compliance: The system must meet all relevant regulatory requirements (e.g., FDA 21 CFR Part 11).

Available Technologies

Various technologies are available for automated vial inspection:

- Vision Systems: Employ high-resolution cameras and advanced image processing algorithms.

- Laser-Based Systems: Utilize laser technology for precise defect detection. These are often used in conjunction with vision systems. Companies such as [insert example company names] offer such advanced solutions.

Choosing the right system involves careful assessment of these factors to ensure optimal performance and regulatory compliance.

Conclusion

Advanced automated inspection systems offer significant advantages for detecting defects in lyophilized vials. These systems increase accuracy, efficiency, and data management, while simultaneously reducing contamination risks. By ensuring the highest levels of product quality and patient safety, automated inspection of lyophilized products is no longer a luxury, but a necessity. Learn more about advanced automated inspection solutions for lyophilized vials and contact industry experts to improve your quality control processes and ensure the highest standards for your lyophilized pharmaceuticals. Consider exploring options in automated lyophilized vial inspection, automated inspection of lyophilized products, and advanced automated inspection for lyophilized pharmaceuticals to find the best solution for your needs.

Featured Posts

-

Why Fans Believe Henry Cavill Could Be Wolverine In Marvels World War Hulk

May 12, 2025

Why Fans Believe Henry Cavill Could Be Wolverine In Marvels World War Hulk

May 12, 2025 -

Understanding Manon Fiorot Her Journey And Future In The Ufc

May 12, 2025

Understanding Manon Fiorot Her Journey And Future In The Ufc

May 12, 2025 -

Injury Report Yankees Vs Giants April 11 13

May 12, 2025

Injury Report Yankees Vs Giants April 11 13

May 12, 2025 -

Michael Johnson Weighs In Tyreek Hill Vs Noah Lyles A Track Showdown

May 12, 2025

Michael Johnson Weighs In Tyreek Hill Vs Noah Lyles A Track Showdown

May 12, 2025 -

Become Baba Yaga A John Wick Experience In Las Vegas

May 12, 2025

Become Baba Yaga A John Wick Experience In Las Vegas

May 12, 2025