Addressing OEM Supply Chain & Country-of-Origin Concerns: SG Wireless' Enhanced Manufacturing Strategy

Table of Contents

Mitigating Supply Chain Risks for OEMs

OEMs face numerous hurdles in today's globalized market. Geopolitical instability, natural disasters, and unexpected component shortages can cripple production and damage reputations. Building supply chain resilience is paramount. SG Wireless takes a proactive approach to risk mitigation by implementing several key strategies:

- Diversified Sourcing of Components: We avoid over-reliance on single suppliers by strategically sourcing components from multiple qualified vendors across diverse geographical locations. This supplier diversification minimizes the impact of disruptions affecting any one region.

- Strategic Partnerships with Reliable Suppliers: We cultivate long-term relationships with trusted suppliers, ensuring a consistent supply of high-quality components. These partnerships are built on mutual trust, open communication, and shared commitment to quality.

- Robust Inventory Management Systems: Our sophisticated inventory management systems employ advanced forecasting techniques and real-time data analytics to optimize stock levels, minimizing the risk of stockouts while avoiding excessive inventory holding costs. This ensures inventory optimization.

- Nearshoring Initiatives: We are actively exploring near-shoring opportunities to reduce lead times and enhance responsiveness to changing market demands, thereby strengthening our supply chain resilience.

- Advanced Supply Chain Visibility Tools and Data Analytics: We leverage advanced data analytics and real-time tracking to gain complete visibility into our supply chain, enabling us to proactively identify and address potential disruptions before they impact production. This allows for effective risk mitigation strategies.

Enhanced Transparency in Country of Origin

The demand for transparency in country-of-origin labeling is rapidly increasing. Consumers are more conscious than ever of where their products are made, and OEMs benefit from clear labeling by building trust and strengthening their brand reputation. Meeting compliance requirements is also crucial. SG Wireless is committed to supply chain transparency:

- Detailed Documentation of the Manufacturing Process: We maintain meticulous records of every stage of the manufacturing process, providing OEMs with complete traceability of their products.

- Traceability of Components Throughout the Supply Chain: Our systems track components from their origin to the finished product, ensuring complete accountability and product authenticity.

- Clear and Accurate Country of Origin Labeling on All Products: We comply with all relevant regulations and ensure accurate and unambiguous country-of-origin labeling on each product.

- Open Communication with OEMs Regarding Sourcing and Manufacturing: We maintain open communication with our OEM partners, providing regular updates and addressing any concerns regarding sourcing and manufacturing processes. This promotes supply chain transparency.

Improving Manufacturing Efficiency and Quality

Efficient manufacturing is directly linked to mitigating supply chain risks. Reduced lead times and improved quality control minimize disruptions and build customer confidence. SG Wireless continuously invests in enhancing its manufacturing processes:

- Investment in Advanced Manufacturing Technologies: We utilize cutting-edge technologies to automate processes, improve accuracy, and enhance overall efficiency.

- Implementation of Lean Manufacturing Principles: We have implemented lean manufacturing principles to streamline our operations, reduce waste, and optimize resource utilization, contributing to improved manufacturing efficiency.

- Stringent Quality Control Measures Throughout the Process: Rigorous quality checks are performed at every stage of production, ensuring that only products meeting the highest standards are shipped. This guarantees superior quality control.

- Regular Audits and Certifications (e.g., ISO): We adhere to the highest industry standards and undergo regular audits to maintain certifications such as ISO 9001, demonstrating our commitment to process optimization.

Case Studies and Success Stories

[Insert 1-2 concise case studies showcasing successful partnerships and quantifiable results. Examples: "Reduced lead times by 15% for Client X," "Improved on-time delivery rate to 99% for Client Y."]

Conclusion

SG Wireless' enhanced manufacturing strategy offers OEMs significant advantages: reduced OEM supply chain risks, improved country of origin transparency, and enhanced manufacturing efficiency. Our commitment to supply chain resilience and open communication ensures our partners can focus on their core business, confident in the quality, integrity, and timely delivery of their products. Partner with SG Wireless to optimize your OEM supply chain and ensure transparent country of origin labeling. Contact us today at [phone number] or [email address] to discuss your specific needs.

Featured Posts

-

Remembering The Holocaust Meta Israels Annual Instagram Project Returns

May 26, 2025

Remembering The Holocaust Meta Israels Annual Instagram Project Returns

May 26, 2025 -

Rtbf Et Les Diables Rouges Analyse D Une Dynamique Renouvelee

May 26, 2025

Rtbf Et Les Diables Rouges Analyse D Une Dynamique Renouvelee

May 26, 2025 -

Iptv Illegal Rtbf Et Rtl Belgium Lancent Une Offensive Contre Le Piratage

May 26, 2025

Iptv Illegal Rtbf Et Rtl Belgium Lancent Une Offensive Contre Le Piratage

May 26, 2025 -

Bayern Faces Goalkeeping Crisis Neuers Injury A Major Blow

May 26, 2025

Bayern Faces Goalkeeping Crisis Neuers Injury A Major Blow

May 26, 2025 -

Neuers Injury A Significant Setback For Bayern Munichs Season

May 26, 2025

Neuers Injury A Significant Setback For Bayern Munichs Season

May 26, 2025

Latest Posts

-

Apples New I Phone Feature A Must Have For Formula 1 Fans

May 26, 2025

Apples New I Phone Feature A Must Have For Formula 1 Fans

May 26, 2025 -

Pogacars Tour Of Flanders Effort A Strava Analysis

May 26, 2025

Pogacars Tour Of Flanders Effort A Strava Analysis

May 26, 2025 -

Tadej Pogacars Tour Of Flanders Strava Data No Flag This Year

May 26, 2025

Tadej Pogacars Tour Of Flanders Strava Data No Flag This Year

May 26, 2025 -

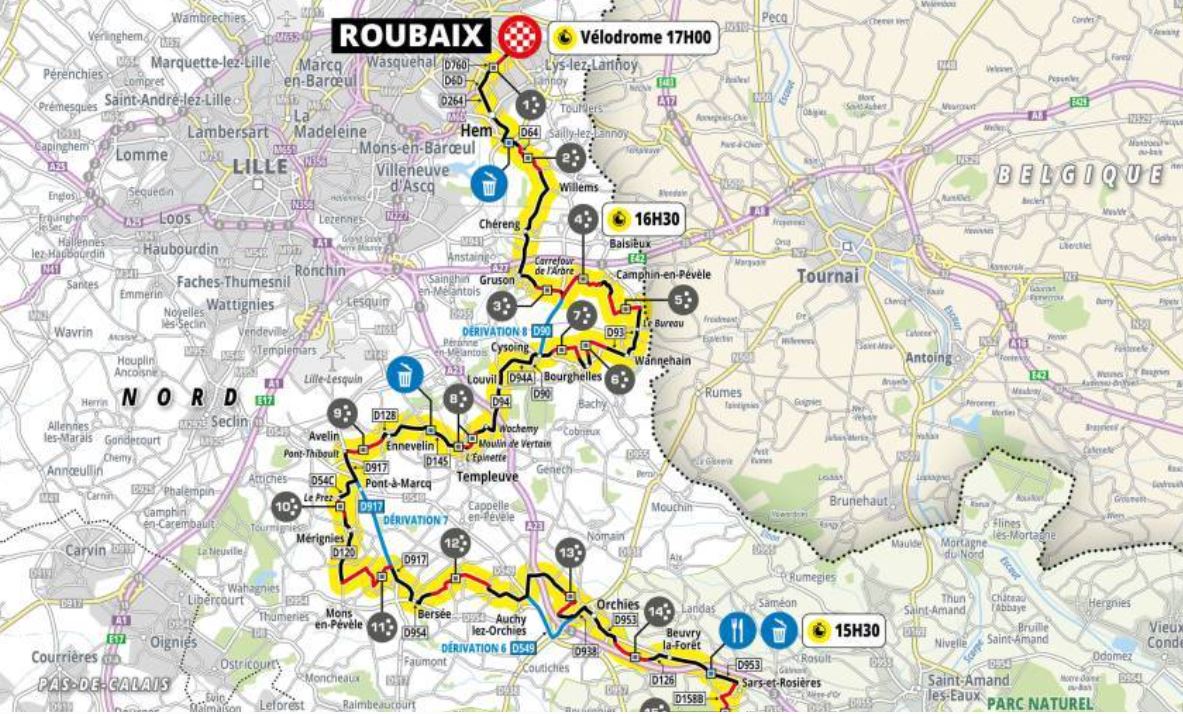

Exploring The Tech Massive Tires And Ingenious Hacks At Paris Roubaix 2025

May 26, 2025

Exploring The Tech Massive Tires And Ingenious Hacks At Paris Roubaix 2025

May 26, 2025 -

Gravel Bike Technology At Paris Roubaix 2025 A Look At The Gear

May 26, 2025

Gravel Bike Technology At Paris Roubaix 2025 A Look At The Gear

May 26, 2025