Analyzing Big Rig ROCK Report 3.12 Data: Laser 101.7 Insights

Table of Contents

The ROCK Report is a crucial diagnostic tool for big rig maintenance and performance monitoring. It provides a comprehensive overview of various vehicle systems. Laser 101.7 readings, a specific component of the 3.12 report, offer critical insights into wheel alignment and suspension health, directly impacting safety, fuel efficiency, and tire life.

Understanding the ROCK Report 3.12 Structure

The ROCK Report 3.12 is structured to provide a snapshot of your vehicle's health at a specific point in time. Understanding its data fields is crucial for effective analysis and preventative maintenance.

Data Fields and Their Significance

The ROCK Report 3.12 includes several key data fields relevant to heavy vehicle maintenance and diagnostics. Let's examine those most important to our understanding of Laser 101.7 readings:

- Date/Time: Indicates when the data was recorded, allowing you to track changes over time.

- Vehicle ID: Unique identifier for each truck in your fleet, enabling individual vehicle performance tracking.

- Laser 101.7 Reading: The core focus of this article, providing crucial data on wheel alignment and suspension. Units are typically in millimeters or degrees, depending on the specific sensor.

- Other Sensor Readings: Data from other sensors (e.g., tire pressure, brake pad wear) can be correlated with Laser 101.7 to provide a holistic view of vehicle health.

Example: A sample entry might show: Date/Time: 2024-10-27 14:30, Vehicle ID: TRUCK123, Laser 101.7 Reading: 2.5 mm, Tire Pressure (Front Left): 80 PSI. This shows a slightly elevated Laser 101.7 reading, which needs further investigation.

Interpreting Laser 101.7 Readings

Laser 101.7 typically measures the deviation from ideal wheel alignment and suspension parameters. Understanding the normal ranges is critical. Deviations from these norms can indicate significant problems.

- Normal Range: Typically within a +/- 1-2 mm range (values may vary depending on vehicle manufacturer specifications). Refer to your vehicle's manual for the precise normal range.

- Abnormal Readings: Readings outside the normal range can indicate issues like:

- Uneven tire wear

- Steering wheel pull

- Suspension component damage or wear

- Brake system problems

- Reduced fuel efficiency

[Insert a graph or chart here showing a typical range for Laser 101.7 readings and examples of readings indicating potential problems. Clearly label the axes and include a legend.]

Advanced ROCK Report 3.12 Data Analysis Techniques

Effective analysis of your ROCK Report data, especially Laser 101.7 readings, requires advanced techniques. This involves visualizing the data and identifying trends.

Data Visualization and Trend Analysis

Visualizing Laser 101.7 data over time is crucial for identifying patterns and predicting potential problems.

- Tools: Spreadsheet software (Excel, Google Sheets), dedicated data visualization tools (Tableau, Power BI), or even custom-built dashboards can be used to effectively visualize this data.

- Correlation: Comparing Laser 101.7 data with other data points in the report, such as tire pressure, brake wear, and fuel consumption, can provide a more complete picture of your vehicle's condition.

[Insert a sample graph here demonstrating a trend of increasing Laser 101.7 readings over several weeks, highlighting a potential problem.]

Identifying and Troubleshooting Potential Issues

By analyzing trends and patterns in Laser 101.7 data, you can proactively identify and address mechanical issues.

- Troubleshooting: A step-by-step approach may include:

- Identify consistent deviations from the normal range of Laser 101.7 readings.

- Correlate these deviations with other data points in the ROCK Report.

- Inspect relevant vehicle components (tires, suspension, brakes).

- Implement necessary repairs or adjustments.

- Case Study: A truck experienced gradually increasing Laser 101.7 readings over several weeks. Analyzing the data alongside tire pressure readings revealed uneven wear on the front left tire. Replacing the tire resolved the issue and prevented further damage.

Optimizing Big Rig Maintenance using Laser 101.7 Insights

Understanding and utilizing Laser 101.7 data allows for proactive maintenance, saving time and money.

Predictive Maintenance Strategies

Laser 101.7 data enables predictive maintenance. By setting thresholds and alerts, you can anticipate potential problems.

- Thresholds & Alerts: Set up alerts when Laser 101.7 readings exceed predefined limits. This triggers proactive maintenance before a minor issue becomes a major breakdown.

- Proactive Schedules: Shift from reactive to proactive maintenance, scheduling service based on data-driven insights rather than relying solely on fixed intervals.

Improving Fuel Efficiency and Reducing Operational Costs

Proper wheel alignment and suspension health, accurately reflected in Laser 101.7 readings, significantly impact fuel consumption.

- Fuel Savings: Addressing alignment and suspension issues identified by Laser 101.7 data can improve fuel efficiency by up to 5-10% (dependent on the severity of the misalignment).

- ROI Calculation: If a misalignment costs $100 in lost fuel per week, and fixing it costs $200, the ROI is positive within two weeks, and significantly positive over a year. The savings are magnified across an entire fleet.

Conclusion: Mastering Big Rig ROCK Report 3.12 Data: Laser 101.7 Insights for Optimized Performance

Mastering the interpretation and analysis of Big Rig ROCK Report 3.12 data, particularly Laser 101.7 readings, is crucial for effective fleet management. By utilizing data visualization, predictive maintenance strategies, and proactive troubleshooting, you can significantly improve your big rig's performance, safety, and overall cost-effectiveness. Don't just react to problems; anticipate them. By leveraging the power of Big Rig ROCK Report analysis and Laser 101.7 insights, you can transform your maintenance strategy into a proactive, data-driven system. To further enhance your understanding and skills in analyzing your Big Rig ROCK Report data, explore our comprehensive online resources or consult with our expert team. Take control of your fleet's maintenance and unlock significant cost savings and operational efficiencies!

Featured Posts

-

Qmrt Qst Njah Snaet Alaflam Alqtryt

May 23, 2025

Qmrt Qst Njah Snaet Alaflam Alqtryt

May 23, 2025 -

Zimbabwes Away Test Victory In Sylhet Breaking The 2021 Barrier

May 23, 2025

Zimbabwes Away Test Victory In Sylhet Breaking The 2021 Barrier

May 23, 2025 -

Cat Deeley Shares Rare Photos Of Her Sons In Stylish Ski Gear

May 23, 2025

Cat Deeley Shares Rare Photos Of Her Sons In Stylish Ski Gear

May 23, 2025 -

Trinidad Trip Curtailed Dancehall Artist Responds To New Travel Rules Receives Kartels Backing

May 23, 2025

Trinidad Trip Curtailed Dancehall Artist Responds To New Travel Rules Receives Kartels Backing

May 23, 2025 -

F1 2024 Mc Larens Pace Setting Performance

May 23, 2025

F1 2024 Mc Larens Pace Setting Performance

May 23, 2025

Latest Posts

-

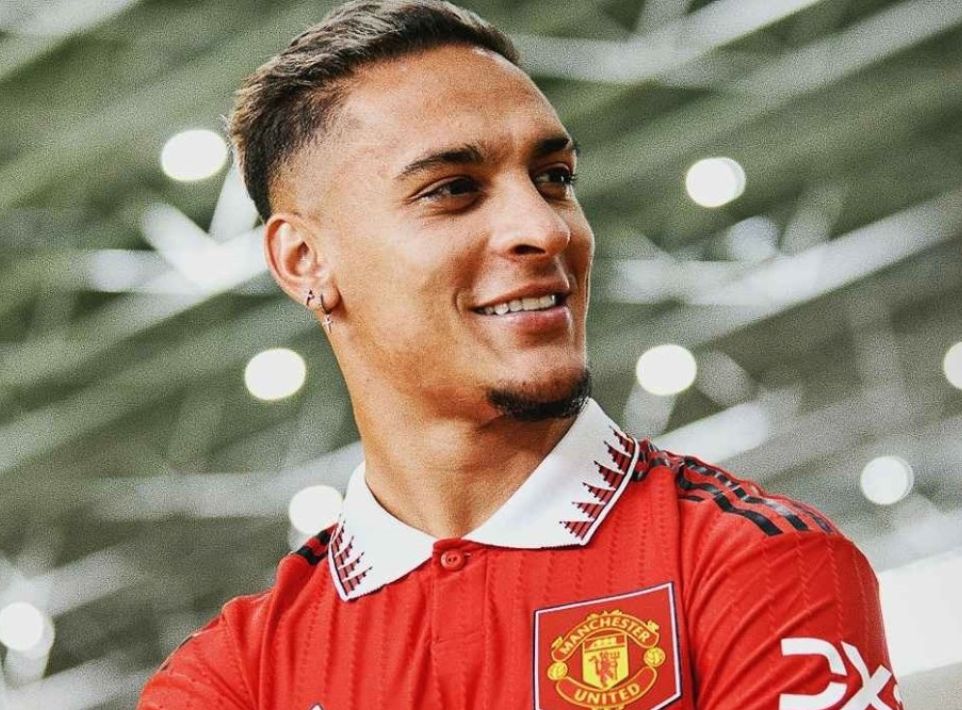

Revealed Antonys Close Call With Manchester Uniteds Biggest Rival

May 23, 2025

Revealed Antonys Close Call With Manchester Uniteds Biggest Rival

May 23, 2025 -

Antonys Rejected Offer A Man Utd Rivals Pursuit

May 23, 2025

Antonys Rejected Offer A Man Utd Rivals Pursuit

May 23, 2025 -

Has Noussair Mazraoui Proven To Be Manchester Uniteds Top Signing

May 23, 2025

Has Noussair Mazraoui Proven To Be Manchester Uniteds Top Signing

May 23, 2025 -

Jaap Stam Ten Hags Man United Spending A Setback

May 23, 2025

Jaap Stam Ten Hags Man United Spending A Setback

May 23, 2025 -

The Untold Story Antony And Manchester Uniteds Arch Rivals

May 23, 2025

The Untold Story Antony And Manchester Uniteds Arch Rivals

May 23, 2025