BYD Case Study: Examining Their Dominance In EV Battery Manufacturing

Table of Contents

BYD's Blade Battery Technology: A Game Changer

BYD's success is significantly attributed to its groundbreaking Blade Battery technology. This innovative approach to EV battery design has redefined industry standards.

Technological Innovation and Advantages

The Blade Battery's unique design, a thin, blade-like cell, offers several key advantages over traditional cylindrical or prismatic cells.

- Increased energy density: Packing more energy into the same space translates directly to longer driving range for EVs.

- Improved safety features: The Blade Battery's design significantly reduces the risk of thermal runaway, a major safety concern in lithium-ion batteries. This enhanced safety is achieved through its unique structure and internal cooling mechanisms.

- Cost-effectiveness: BYD's efficient manufacturing process makes the Blade Battery a competitive option, challenging the cost dominance of other battery technologies.

The Blade Battery's form factor also improves vehicle design and packaging efficiency. Its flat shape allows for more flexible battery pack configurations, maximizing interior space and optimizing vehicle aerodynamics. Compared to bulky cylindrical or prismatic cells, the Blade Battery allows automakers to create more spacious and aesthetically pleasing EVs.

Impact on Vehicle Performance and Range

The Blade Battery's superior energy density directly translates into improved EV performance and range.

- Increased driving range per charge: BYD EVs equipped with Blade Batteries boast significantly longer driving ranges compared to models using other battery technologies.

- Faster charging times (in select models): While not universally faster charging, certain BYD models using Blade Batteries have shown improvements in charging speeds.

- Enhanced vehicle performance: The improved energy delivery of the Blade Battery can also contribute to enhanced acceleration and overall vehicle performance.

For instance, the BYD Atto 3 boasts an impressive range, largely thanks to its Blade Battery technology. Independent test results frequently confirm the extended range claims made by BYD. This real-world performance has significantly contributed to BYD's market success.

Vertical Integration: Control Over the Supply Chain

BYD's vertical integration strategy is another cornerstone of its success in the EV battery manufacturing sector. This strategy gives them unparalleled control over their supply chain.

From Raw Materials to Finished Product

BYD's vertical integration extends from the mining of raw materials to the final assembly of battery packs. This comprehensive approach offers numerous advantages:

- Cost control: Direct control over the entire supply chain allows BYD to optimize costs at each stage of production.

- Secure supply chain: Minimizes the risk of supply disruptions and ensures a stable supply of materials, a major advantage in a volatile global market.

- Reduced reliance on external suppliers: Reduces vulnerability to external supplier issues, including price hikes and quality fluctuations.

- Improved quality control: Direct oversight at each stage ensures consistent quality throughout the manufacturing process.

This level of control is a significant competitive advantage. It allows BYD to respond quickly to market demands, maintain consistent product quality, and ultimately offer competitive pricing.

Strategic Partnerships and Acquisitions

BYD has strategically formed partnerships and made acquisitions to further strengthen its vertical integration.

- Key Partnerships and Acquisitions: (Specific examples of partnerships and acquisitions should be listed here, with details on their contribution to BYD's vertical integration strategy, e.g., securing lithium supplies, acquiring technology for advanced battery chemistries).

- Securing Key Raw Materials: These actions ensure access to vital raw materials like lithium, cobalt, and nickel, mitigating the risks associated with volatile commodity markets.

- Enhancing Technological Capabilities: Strategic acquisitions have also helped BYD enhance its technological capabilities in battery design, manufacturing, and recycling.

Market Share and Global Expansion

BYD's success isn't just limited to technological innovation and vertical integration; it also reflects a robust market strategy.

Dominating the Chinese EV Market

BYD currently holds a significant market share in the Chinese EV market. Several factors contribute to this success:

- Market share statistics: (Include specific data on BYD's market share in China.)

- Pricing strategies: BYD offers competitive pricing, making its EVs accessible to a wider range of consumers.

- Consumer preferences: BYD's vehicles are well-regarded for their quality, features, and performance.

- Government policies: Supportive government policies in China have also played a role in fostering the growth of the domestic EV industry.

BYD's understanding of the local market and its ability to tailor its offerings to Chinese consumer preferences have been crucial to their success.

Global Ambitions and International Growth

BYD is rapidly expanding its presence into international markets.

- Target markets: BYD is targeting key markets in Europe, North America, and other regions.

- Strategies for market entry: BYD's international expansion strategy includes establishing local partnerships, setting up manufacturing facilities, and adapting its vehicles to meet the specific needs of different markets.

- Challenges and opportunities: Navigating regulatory hurdles, addressing cultural preferences, and managing competition are some of the challenges BYD faces in international markets. However, the global shift towards electric vehicles presents significant growth opportunities.

BYD's commitment to global expansion underscores its long-term vision of becoming a leading player in the global EV industry.

Conclusion

BYD's dominance in EV battery manufacturing is a testament to its integrated strategy combining technological innovation (the Blade Battery), effective vertical integration, and strategic market expansion. Their success highlights the importance of technological leadership, secure supply chains, and adept navigation of the global electric vehicle market. To stay ahead in the rapidly evolving EV landscape, businesses must pay close attention to BYD's innovative approach to BYD EV battery manufacturing and consider adopting similar strategies to achieve success in this competitive sector. Learn more about the latest advancements in BYD electric vehicle battery technology by researching their latest product announcements and industry reports.

Featured Posts

-

Doom The Dark Ages Reviews Go Live Download Size Announced

May 13, 2025

Doom The Dark Ages Reviews Go Live Download Size Announced

May 13, 2025 -

Di Caprios Met Gala 2024 Debut Alongside Vittoria Ceretti

May 13, 2025

Di Caprios Met Gala 2024 Debut Alongside Vittoria Ceretti

May 13, 2025 -

Wildfires In The Uk Devastation For Rare And Endangered Species

May 13, 2025

Wildfires In The Uk Devastation For Rare And Endangered Species

May 13, 2025 -

Doom Dark Ages Inspiration How Classic Doom Influences Modern Development

May 13, 2025

Doom Dark Ages Inspiration How Classic Doom Influences Modern Development

May 13, 2025 -

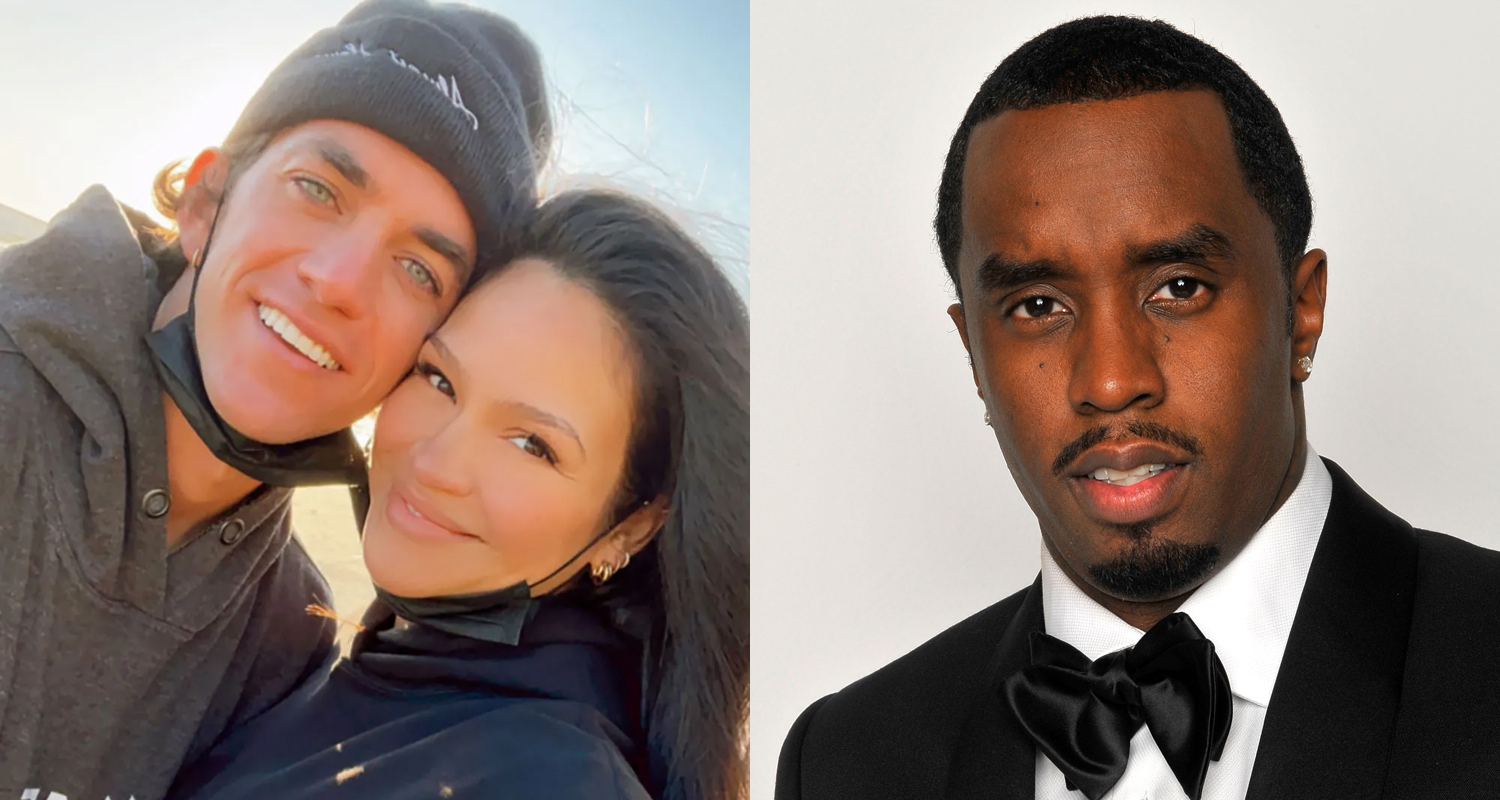

Diddy Sex Trafficking Trial Cassies Husband Alex Fine Offers Support

May 13, 2025

Diddy Sex Trafficking Trial Cassies Husband Alex Fine Offers Support

May 13, 2025

Latest Posts

-

Final Seal Release Marks Closure Of Pieterburen Rescue Center After 50 Years

May 13, 2025

Final Seal Release Marks Closure Of Pieterburen Rescue Center After 50 Years

May 13, 2025 -

End Of An Era Pieterburen Seal Rescue Centers Final Seal Release

May 13, 2025

End Of An Era Pieterburen Seal Rescue Centers Final Seal Release

May 13, 2025 -

Pieterburens Seal Rescue Center A Legacy Ends Final Seals Released

May 13, 2025

Pieterburens Seal Rescue Center A Legacy Ends Final Seals Released

May 13, 2025 -

Easter Travel Chaos Schiphol Road And Ferry Peak Day Predictions

May 13, 2025

Easter Travel Chaos Schiphol Road And Ferry Peak Day Predictions

May 13, 2025 -

Schiphol Airport Roads And Ferries Easter Holiday Traffic Predictions

May 13, 2025

Schiphol Airport Roads And Ferries Easter Holiday Traffic Predictions

May 13, 2025