Ford's EV Strategy: Sharing Battery Plant Production With Nissan

Table of Contents

The Growing Importance of Battery Cell Production in the EV Market

Battery technology is the lifeblood of the EV revolution. Without efficient, cost-effective, and sustainably sourced batteries, widespread EV adoption remains a distant dream. The challenges are multifaceted: securing raw materials like lithium, cobalt, and nickel; scaling up manufacturing capacity to meet the burgeoning demand; and constantly pushing the boundaries of battery technology itself – striving for increased energy density, faster charging times, and longer lifespans. Major players like Tesla and Volkswagen are already aggressively pursuing their own battery strategies, highlighting the intense competition.

- High demand for EV batteries: The global shift towards electric mobility is driving unprecedented demand.

- Limited global production capacity: Current production struggles to keep pace with the rapidly growing market.

- Technological race for improved battery density and charging times: Innovation is crucial for enhancing EV performance and consumer appeal.

- Geopolitical implications of battery supply chains: The sourcing of raw materials introduces geopolitical complexities and risks.

Ford and Nissan's Joint Venture: A Deep Dive

Ford and Nissan's collaboration represents a significant step in securing the future of EV production. The details of this joint venture are still unfolding, but it promises a substantial impact. The partnership will likely involve the establishment of one or more battery plants in strategically chosen locations, focusing on high-volume production of advanced battery cells. While the exact investment amounts and production capacity remain undisclosed, the collaboration anticipates significant economies of scale, allowing both companies to leverage their collective expertise and resources. The types of battery cells produced will likely include both Lithium Iron Phosphate (LFP) and Nickel Manganese Cobalt (NMC) chemistries, catering to diverse EV models and market needs.

- Shared investment costs and risk reduction: Pooling resources mitigates financial burdens for both partners.

- Economies of scale achieved through collaboration: Mass production lowers per-unit costs, making EVs more affordable.

- Access to Nissan's battery technology and expertise: Nissan's established battery technology provides a crucial advantage.

- Strengthened competitiveness in the EV market: The partnership gives both companies a powerful edge in the growing EV race.

Strategic Implications of Ford's EV Strategy with Nissan

This joint venture carries profound strategic implications for both Ford and Nissan. For Ford, it significantly boosts their EV production capacity, reducing reliance on external suppliers and bolstering their ambitious electric vehicle targets. For Nissan, it allows them to leverage their existing battery expertise on a larger scale, enhancing their market position. The partnership opens avenues for future collaborations, potentially extending beyond battery production to encompass other aspects of EV technology and development. Furthermore, the joint venture holds significant environmental and sustainability benefits, promoting responsible sourcing of raw materials and reducing the overall carbon footprint of EV production.

- Enhanced EV production capacity for Ford: Addressing a key bottleneck in EV manufacturing.

- Improved cost efficiency for battery cell production: Achieving economies of scale through shared resources.

- Reduced reliance on external battery suppliers: Securing a stable and reliable supply chain.

- Strengthened market position for both companies: Boosting their competitiveness in the global EV arena.

- Potential for technology sharing and innovation: Accelerating advancements in battery technology.

Challenges and Risks of the Joint Venture

Despite the significant potential, this joint venture faces inherent challenges. Maintaining a harmonious and productive partnership between two independent companies with potentially differing corporate cultures requires careful management. Market fluctuations and rapid technological advancements in the battery sector pose ongoing risks, demanding adaptability and responsiveness from both partners. Geopolitical instability and the potential for disruptions in the supply chain of critical raw materials add further complexity.

- Maintaining a productive partnership: Effective communication and collaboration are vital for success.

- Managing differing corporate cultures: Integrating different organizational structures and approaches requires skillful leadership.

- Responding to changes in market demand: Flexibility and agility are crucial in a dynamic market.

- Mitigating supply chain disruptions: Robust risk management strategies are essential to secure raw material sourcing.

Conclusion: Ford's EV Strategy and the Future of its Nissan Partnership

Ford's strategic partnership with Nissan for battery production is a pivotal element of their overall EV strategy. This joint venture significantly enhances Ford's ability to meet the growing demand for electric vehicles by securing a crucial aspect of the EV supply chain. The collaboration promises economies of scale, reduced risk, and access to cutting-edge technology, strengthening both companies' positions in the competitive EV market. While challenges exist, the long-term implications for both Ford and the broader automotive industry are substantial. To learn more about Ford's EV strategy and the advancements in electric vehicle technology, stay tuned for future articles and updates.

Featured Posts

-

Trans Australia Run The Race To Break The World Record

May 22, 2025

Trans Australia Run The Race To Break The World Record

May 22, 2025 -

Mulhouse Un Concert Hellfest Au Noumatrouff

May 22, 2025

Mulhouse Un Concert Hellfest Au Noumatrouff

May 22, 2025 -

Betalbaarheid Nederlandse Woningen Analyse Van Abn Amro En Geen Stijls Standpunten

May 22, 2025

Betalbaarheid Nederlandse Woningen Analyse Van Abn Amro En Geen Stijls Standpunten

May 22, 2025 -

Googles Ai A Deep Dive Into Investor Expectations And Performance

May 22, 2025

Googles Ai A Deep Dive Into Investor Expectations And Performance

May 22, 2025 -

Blake Lively Faces Lawsuit All The Details On The Justin Baldoni Case And Celebrity Involvement

May 22, 2025

Blake Lively Faces Lawsuit All The Details On The Justin Baldoni Case And Celebrity Involvement

May 22, 2025

Latest Posts

-

Thong Tin Du An Cau Ma Da Khoi Cong Thang 6 Ket Noi Dong Nai Va Binh Phuoc

May 22, 2025

Thong Tin Du An Cau Ma Da Khoi Cong Thang 6 Ket Noi Dong Nai Va Binh Phuoc

May 22, 2025 -

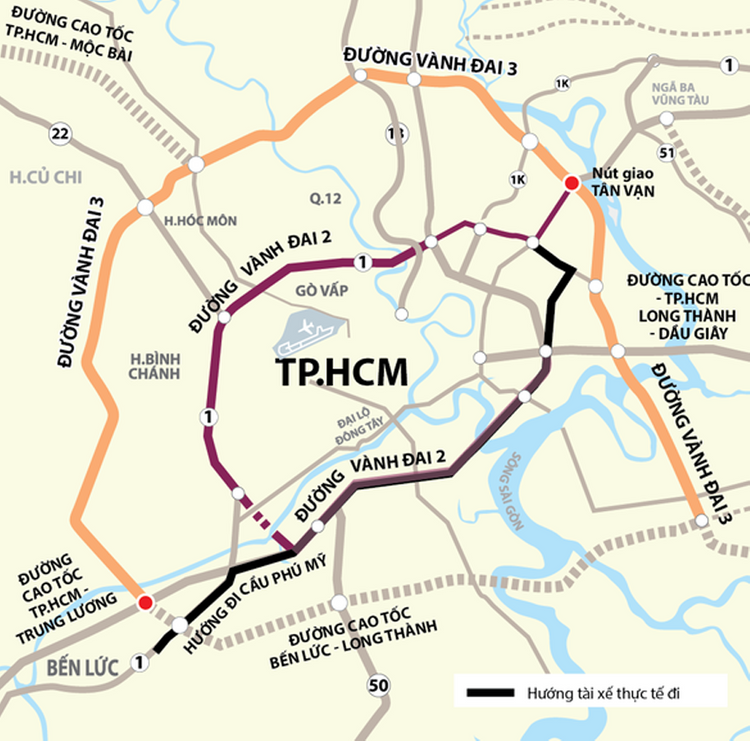

Ket Noi Giao Thong Tp Hcm Ba Ria Vung Tau Nhung Tuyen Duong Chinh

May 22, 2025

Ket Noi Giao Thong Tp Hcm Ba Ria Vung Tau Nhung Tuyen Duong Chinh

May 22, 2025 -

Thu Thach Chay Bo 200 Nguoi Ket Noi Dak Lak Va Phu Yen

May 22, 2025

Thu Thach Chay Bo 200 Nguoi Ket Noi Dak Lak Va Phu Yen

May 22, 2025 -

7 Tuyen Ket Noi Quan Trong Tp Hcm Long An Dau Tu Uu Tien

May 22, 2025

7 Tuyen Ket Noi Quan Trong Tp Hcm Long An Dau Tu Uu Tien

May 22, 2025 -

Cau Ma Da Noi Dong Nai Binh Phuoc Du Kien Khoi Cong Thang 6 2024

May 22, 2025

Cau Ma Da Noi Dong Nai Binh Phuoc Du Kien Khoi Cong Thang 6 2024

May 22, 2025