Innovation And Technology Shaping The Vaccine Packaging Market

Table of Contents

Advanced Materials for Enhanced Vaccine Protection

Traditional vaccine packaging materials are increasingly being replaced by advanced solutions offering superior protection and sustainability. The need to maintain the integrity of temperature-sensitive vaccines during transport and storage is paramount. This requires packaging solutions that minimize temperature fluctuations and provide robust barriers against moisture, oxygen, and other environmental factors.

-

The Shift to Advanced Polymers and Composites: Modern vaccine packaging utilizes advanced polymers and composites, offering significantly improved insulation and barrier properties compared to traditional materials. These materials are engineered to withstand the rigors of transportation and storage, ensuring consistent vaccine efficacy.

-

Maintaining Vaccine Integrity: The core function of vaccine packaging is to maintain the potency and safety of the vaccine. Materials designed to minimize temperature excursions, even during unexpected delays or disruptions in the cold chain, are crucial. This includes features like vacuum insulated panels (VIPs) that significantly enhance insulation performance.

-

Sustainable and Eco-Friendly Solutions: The environmental impact of packaging is increasingly important. The industry is shifting towards biodegradable and recyclable materials to minimize waste and reduce the carbon footprint of vaccine distribution. Bio-based polymers and compostable materials are gaining traction as sustainable alternatives.

-

Specific Material Examples: Examples include the use of specialized films with enhanced barrier properties against moisture and oxygen, as well as the increased adoption of lightweight, high-performance insulation materials to reduce transport costs and environmental impact.

Smart Packaging Technologies for Enhanced Cold Chain Management

Smart vaccine packaging is revolutionizing cold chain management by integrating sensors and data loggers directly into the packaging itself. This enables real-time monitoring of critical parameters like temperature, humidity, and location, significantly improving vaccine safety and distribution efficiency.

-

Real-Time Temperature Monitoring: Embedded sensors continuously monitor the temperature of the vaccine shipment, providing crucial data throughout the entire journey. This allows for immediate identification and mitigation of any temperature excursions that could compromise vaccine efficacy.

-

RFID and GPS Tracking: Radio-Frequency Identification (RFID) tags and GPS tracking systems provide real-time location data, offering complete visibility of vaccine shipments. This helps optimize logistics, prevent loss or theft, and ensure timely delivery to vaccination sites.

-

Improved Logistics and Reduced Waste: The data generated by smart packaging allows for proactive management of the cold chain. Logistics teams can quickly respond to potential issues, minimizing delays and reducing the risk of vaccine spoilage or degradation. This significantly reduces waste and ensures that more vaccines reach their intended recipients.

-

Impact on Vaccine Distribution: Smart packaging solutions are already making a significant impact on global vaccine distribution, particularly in remote or challenging environments where maintaining consistent cold chain integrity is particularly difficult.

Automation and Efficiency in Vaccine Packaging Processes

Automation is playing an increasingly important role in streamlining vaccine packaging processes, enhancing efficiency, and reducing costs. Advanced technologies are optimizing every stage of the process, from filling and sealing to labeling and serialization.

-

Automated Packaging Lines: High-speed automated packaging lines significantly increase throughput compared to manual processes. This allows for faster and more efficient packaging of large quantities of vaccines, meeting the demands of mass vaccination campaigns.

-

Robotics and AI in Vaccine Packaging: The integration of robotics and artificial intelligence (AI) further enhances speed, accuracy, and consistency. AI-powered systems can optimize packaging line parameters, detect defects, and improve overall quality control.

-

Minimizing Human Error: Automation reduces the risk of human error, a crucial factor in ensuring the consistent quality and safety of vaccine packaging. Automated systems ensure that each package meets stringent quality standards.

-

Automated Processes: Examples of automated processes include automated vial filling, high-speed sealing and capping, and automated labeling and coding systems, all contributing to improved efficiency and reduced costs.

The Role of Serialization and Track & Trace Systems

Serialization and track and trace systems are vital for combating vaccine counterfeiting and ensuring the authenticity of each dose. These systems provide unparalleled visibility into the vaccine supply chain, enhancing security and public health.

-

Combating Counterfeit Vaccines: Serialization assigns a unique identifier to each vaccine dose, making it virtually impossible to replicate or counterfeit. This is crucial in protecting public health and preventing the distribution of potentially harmful fake vaccines.

-

Improved Supply Chain Visibility: Track and trace systems provide a comprehensive audit trail for every vaccine dose, from manufacturing to administration. This allows for complete transparency and accountability throughout the entire supply chain.

-

Maintaining Vaccine Integrity: Serialization and track and trace systems play a critical role in maintaining the integrity of the vaccine supply chain, ensuring that vaccines reach their intended destinations in a safe and secure manner.

-

Global Regulations and Standards: Many countries have implemented regulations and standards requiring vaccine serialization and track and trace systems, reflecting the growing importance of these technologies in safeguarding public health.

Conclusion

The vaccine packaging market is undergoing a dramatic transformation driven by technological innovation. Advanced materials, smart packaging technologies, automation, and serialization are enhancing the safety, efficacy, and distribution efficiency of vaccines globally. These advancements are not just improvements; they are critical for protecting public health and ensuring equitable access to vaccines worldwide. The future of vaccine packaging lies in continued innovation, ensuring that every dose reaches its recipient safely and effectively.

Call to Action: Stay informed about the latest innovations in the rapidly evolving vaccine packaging market. Explore the latest advancements in vaccine packaging solutions and discover how these technologies can improve your organization’s vaccine distribution strategies and protect public health.

Featured Posts

-

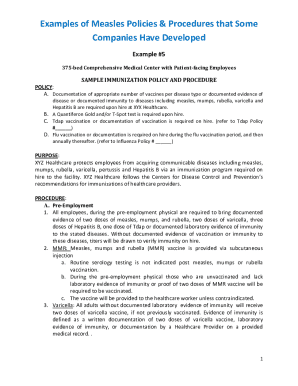

Addressing The Persistence Of Measles Strategies For Elimination

May 30, 2025

Addressing The Persistence Of Measles Strategies For Elimination

May 30, 2025 -

Live Now Pay Later Options Choosing The Best Plan For Your Needs

May 30, 2025

Live Now Pay Later Options Choosing The Best Plan For Your Needs

May 30, 2025 -

Dansk Arbejdsmiljo Under Lup Stjernes Kritik Af Chefens Opforsel

May 30, 2025

Dansk Arbejdsmiljo Under Lup Stjernes Kritik Af Chefens Opforsel

May 30, 2025 -

Impact Of Trump Tariffs Challenges And Opportunities For Indian Solar Equipment Exporters In Southeast Asia

May 30, 2025

Impact Of Trump Tariffs Challenges And Opportunities For Indian Solar Equipment Exporters In Southeast Asia

May 30, 2025 -

Measles Outbreak Spreads Across Israel Following Texas Case

May 30, 2025

Measles Outbreak Spreads Across Israel Following Texas Case

May 30, 2025

Latest Posts

-

Controversy Surrounds New Beatles Cast Understanding The White Boy Of The Month Criticism

May 31, 2025

Controversy Surrounds New Beatles Cast Understanding The White Boy Of The Month Criticism

May 31, 2025 -

Beatles Casting Announcement Sparks Debate Examining The White Boy Of The Month Reaction

May 31, 2025

Beatles Casting Announcement Sparks Debate Examining The White Boy Of The Month Reaction

May 31, 2025 -

The Beatles Cast Revealed A Look At The White Boy Of The Month Controversy

May 31, 2025

The Beatles Cast Revealed A Look At The White Boy Of The Month Controversy

May 31, 2025 -

Podrobnosti Za Kontuziyata Na Grigor Dimitrov

May 31, 2025

Podrobnosti Za Kontuziyata Na Grigor Dimitrov

May 31, 2025 -

Vzstanovyavane Na Grigor Dimitrov Sled Kontuziya

May 31, 2025

Vzstanovyavane Na Grigor Dimitrov Sled Kontuziya

May 31, 2025