Inside The Hyundai 650: A Car Carrier's Visit To The Ulsan Plant

Table of Contents

The Hyundai 650: A Deep Dive into its Specifications and Capabilities

The Hyundai 650 isn't just any car carrier; it's a meticulously engineered vessel designed for efficient and safe vehicle transportation. Let's examine its key features:

Dimensions and Capacity:

- Length: [Insert Length – e.g., 190 meters]

- Width: [Insert Width – e.g., 32 meters]

- Height: [Insert Height – e.g., 25 meters]

- Capacity: [Insert Capacity – e.g., 6,500 vehicles] This substantial capacity allows the Hyundai 650 to transport a diverse range of Hyundai models, from compact cars to larger SUVs, optimizing shipping efficiency for various vehicle types. Imagine the sheer volume of vehicles this single carrier can move in a single voyage! [Include a high-quality image of the Hyundai 650]

Safety Features and Technology:

The Hyundai 650 incorporates state-of-the-art safety technology to ensure the secure transport of its precious cargo.

- Dynamic Positioning System (DPS): Maintains precise position even in challenging weather conditions.

- Advanced Braking Systems: Provides superior stopping power for enhanced safety.

- GPS Tracking and Monitoring: Real-time tracking of the vessel's location and condition.

- Fuel-Efficient Engines: Minimizes environmental impact through reduced fuel consumption and emissions. This aligns with Hyundai's increasing commitment to sustainability in vehicle transportation and logistics.

Design and Engineering:

The Hyundai 650's design is optimized for efficient loading and unloading.

- Ramps and Elevators: Facilitates smooth and rapid loading and unloading of vehicles.

- Secure Vehicle Restraints: Prevents vehicle movement during transit, ensuring safe transportation.

- Specialized Cargo Handling Equipment: Ensures efficient and damage-free handling of vehicles of various sizes and types. The engineering behind this carrier is a testament to Hyundai's commitment to excellence in its supply chain.

The Journey to Ulsan: A Logistical Masterpiece

Getting the Hyundai 650 to the Ulsan plant involves meticulous planning and execution.

Route Planning and Optimization:

The journey's route isn't arbitrary; it's meticulously planned using advanced route optimization software. Factors considered include:

- Distance and Travel Time: Determining the shortest and most efficient route.

- Weather Conditions: Avoiding areas with potential for severe weather that could delay the journey.

- Traffic Patterns: Minimizing delays due to congestion. This sophisticated route planning is crucial for maintaining Hyundai's just-in-time manufacturing processes.

Port Operations and Handling:

Reaching the port is only half the battle. Efficient port operations are essential.

- Specialized Cranes and Equipment: Used for loading and unloading vehicles onto and off the Hyundai 650.

- Dockside Logistics: Coordination of loading, securing, and documentation processes. [Include an image of vehicles being loaded onto a similar car carrier]

- Port Security and Safety Protocols: Ensuring the safety and security of the cargo and personnel.

Challenges and Solutions:

Despite meticulous planning, challenges can arise.

- Weather Disruptions: Storms or fog can cause delays. Contingency plans, including alternative routes and port options, are implemented.

- Mechanical Issues: Regular maintenance and onboard repair capabilities minimize downtime.

- Port Congestion: Pre-planning and coordination with port authorities help mitigate delays. The efficient management of these challenges is a key factor in Hyundai's ability to maintain a reliable supply chain.

Arrival at the Ulsan Plant: The Final Stage

The Hyundai 650's journey culminates at the Ulsan plant.

Unloading and Inspection:

Upon arrival, the vehicles are unloaded efficiently and thoroughly inspected.

- Damage Assessment: Checking for any damage incurred during transit.

- Quality Control Checks: Ensuring the vehicles meet Hyundai's quality standards.

- Inventory Management: Tracking and recording the arrival of each vehicle.

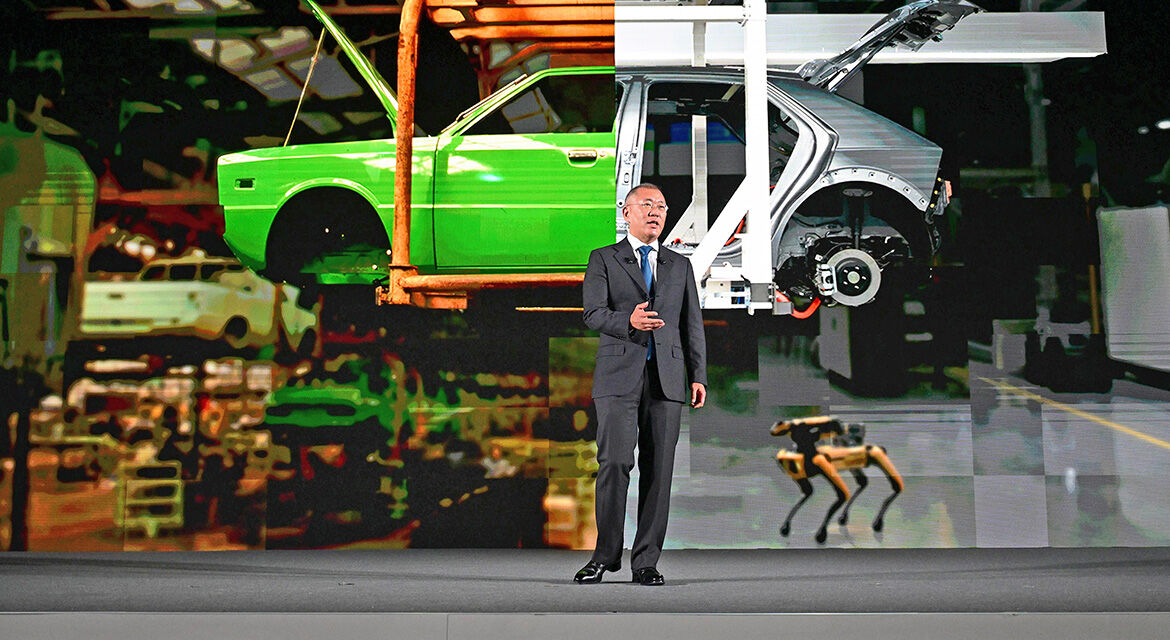

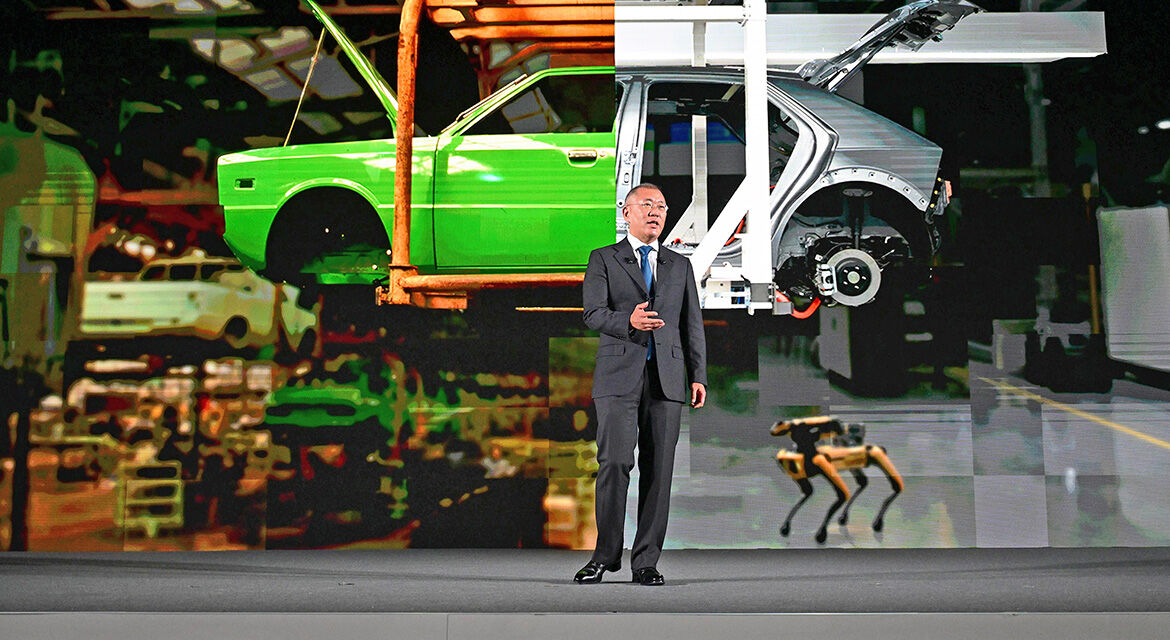

Integration into the Manufacturing Process:

The unloaded vehicles seamlessly integrate into the Ulsan plant's manufacturing process.

- Just-in-Time Delivery: Ensuring parts and components arrive precisely when needed.

- Efficient Material Handling: Minimizing waste and maximizing productivity.

- Streamlined Production: Maintaining a consistent flow of materials to the assembly lines.

The Role of the Hyundai 650 in the Ulsan Plant's Ecosystem:

The Hyundai 650 isn't just a ship; it's a vital link in Hyundai's global supply chain. Its efficiency directly impacts:

- Production Capacity: Ensuring the Ulsan plant receives the necessary vehicles in a timely manner.

- Inventory Management: Minimizing storage costs and maximizing space utilization.

- Overall Profitability: Efficient transportation translates to cost savings and enhanced competitiveness.

Conclusion: The Hyundai 650's Crucial Role in Hyundai's Success

The journey of the Hyundai 650 car carrier highlights the critical role efficient vehicle transportation plays in Hyundai's success. From its impressive specifications to its seamless integration into the Ulsan plant's operations, the Hyundai 650 epitomizes Hyundai's commitment to optimizing its logistics network. Understanding the complexities involved in getting vehicles from origin to the Ulsan plant underscores the importance of robust supply chain management within a global automotive giant. Learn more about the vital role of the Hyundai 650 and other car carriers in the success of Hyundai's Ulsan plant. Explore Hyundai's commitment to efficient vehicle transportation and global logistics!

Featured Posts

-

Did House Of The Dragons Milly Alcock Get An Acting Coach

May 23, 2025

Did House Of The Dragons Milly Alcock Get An Acting Coach

May 23, 2025 -

F1 Season Opener Wolff Expresses Confidence

May 23, 2025

F1 Season Opener Wolff Expresses Confidence

May 23, 2025 -

Ftc Probes Open Ais Chat Gpt Privacy And Data Concerns

May 23, 2025

Ftc Probes Open Ais Chat Gpt Privacy And Data Concerns

May 23, 2025 -

Beyond The Dojo Analyzing The Themes And Symbolism In The Karate Kid

May 23, 2025

Beyond The Dojo Analyzing The Themes And Symbolism In The Karate Kid

May 23, 2025 -

Swiss Alpine Village Evacuates Livestock Landslide Risk Forces Unique Rescue Operation

May 23, 2025

Swiss Alpine Village Evacuates Livestock Landslide Risk Forces Unique Rescue Operation

May 23, 2025

Latest Posts

-

The Tush Push Triumphs Nfl Eases Restrictions On End Zone Celebrations

May 23, 2025

The Tush Push Triumphs Nfl Eases Restrictions On End Zone Celebrations

May 23, 2025 -

Nfls War On End Zone Celebrations Ends The Tush Push Lives On

May 23, 2025

Nfls War On End Zone Celebrations Ends The Tush Push Lives On

May 23, 2025 -

The Nfls Tush Push A Controversial Celebration Survives

May 23, 2025

The Nfls Tush Push A Controversial Celebration Survives

May 23, 2025 -

Why Investors Shouldnt Worry About Elevated Stock Market Valuations Bof A

May 23, 2025

Why Investors Shouldnt Worry About Elevated Stock Market Valuations Bof A

May 23, 2025 -

Are High Stock Valuations Justified Bof As Take For Investors

May 23, 2025

Are High Stock Valuations Justified Bof As Take For Investors

May 23, 2025