Manufacturers Prioritize Cybersecurity: A 41% Increase In Investment

Table of Contents

The Rising Threat Landscape for Manufacturers

The manufacturing sector faces an increasingly complex and dangerous cybersecurity threat landscape. Manufacturers prioritize cybersecurity because the consequences of a successful attack can be devastating.

Increased Frequency and Sophistication of Attacks

- Ransomware attacks: These attacks encrypt critical data and systems, demanding payment for their release. The downtime and data loss can cripple operations. Recent ransomware attacks have cost manufacturers millions of dollars in recovery costs and lost revenue.

- Supply chain attacks: Attackers target vulnerabilities in the supply chain to compromise the manufacturer's systems. This can involve infiltrating suppliers' networks or exploiting weaknesses in software updates.

- Industrial espionage: Competitors or state-sponsored actors may target manufacturers to steal intellectual property, trade secrets, or sensitive customer data.

- Denial-of-service (DoS) attacks: These attacks overwhelm systems, preventing legitimate users from accessing them. This can disrupt production lines and lead to significant financial losses.

The average cost of a cyberattack on a manufacturing company can reach millions, including direct costs like ransom payments, IT recovery, and legal fees, plus indirect costs like lost production, reputational damage, and customer churn. For example, the NotPetya ransomware attack in 2017 caused billions of dollars in damage globally, impacting many manufacturers.

Vulnerabilities in Industrial Control Systems (ICS)

Industrial Control Systems (ICS) and Supervisory Control and Data Acquisition (SCADA) systems control critical manufacturing processes. These systems often rely on older, less secure technologies, making them particularly vulnerable to cyber threats. Legacy systems, lacking modern security features, are a major concern. The lack of regular patching and updates for ICS software also significantly increases the risk of successful attacks. Manufacturers prioritize cybersecurity to address these vulnerabilities.

Key Areas of Cybersecurity Investment by Manufacturers

In response to the growing threat landscape, manufacturers are significantly increasing their investments across several key areas:

Improved Network Security

Manufacturers are investing heavily in robust network security measures, including:

- Next-generation firewalls: These advanced firewalls provide superior protection against sophisticated attacks.

- Intrusion Detection/Prevention Systems (IDS/IPS): These systems monitor network traffic for malicious activity and automatically block threats.

- Secure remote access: With the increasing reliance on remote access to ICS, securing these connections is paramount, often through VPNs and multi-factor authentication (MFA).

- Zero-trust security models: These models assume no implicit trust and verify every user and device before granting access.

Enhanced Endpoint Security

Securing industrial computers, Programmable Logic Controllers (PLCs), and other endpoints is crucial. Manufacturers prioritize cybersecurity by investing in:

- Endpoint Detection and Response (EDR) solutions: These solutions monitor endpoints for malicious activity and provide automated responses to threats.

- Regular security audits and vulnerability assessments: These help identify and address security weaknesses before they can be exploited.

- Microsegmentation: Isolating critical systems on the network reduces the impact of a breach.

Employee Training and Awareness

The human element is often the weakest link in cybersecurity. Manufacturers prioritize cybersecurity through:

- Comprehensive cybersecurity awareness training: Training programs educate employees about phishing scams, social engineering tactics, and best security practices.

- Regular phishing simulations: These simulations test employees' ability to identify and report phishing attempts.

- Security policies and procedures: Clear and well-defined security policies are essential for maintaining a strong security posture.

Investment in Cybersecurity Professionals

The demand for skilled cybersecurity professionals in the manufacturing sector is growing rapidly. However, finding and retaining qualified personnel remains a challenge. Manufacturers are addressing this by:

- Offering competitive salaries and benefits: To attract and retain top talent.

- Investing in employee development and training: To upskill existing staff.

- Outsourcing cybersecurity functions: To leverage external expertise.

Future Trends in Manufacturing Cybersecurity

The cybersecurity landscape is constantly evolving, and manufacturers must adapt to stay ahead of the curve.

Artificial Intelligence (AI) and Machine Learning (ML) in Cybersecurity

AI and ML are revolutionizing cybersecurity by enabling:

- Advanced threat detection: AI algorithms can analyze vast amounts of data to identify anomalies and potential threats in real-time.

- AI-powered threat intelligence platforms: These platforms provide insights into emerging threats and vulnerabilities.

- Predictive analytics: AI can predict future attacks based on historical data.

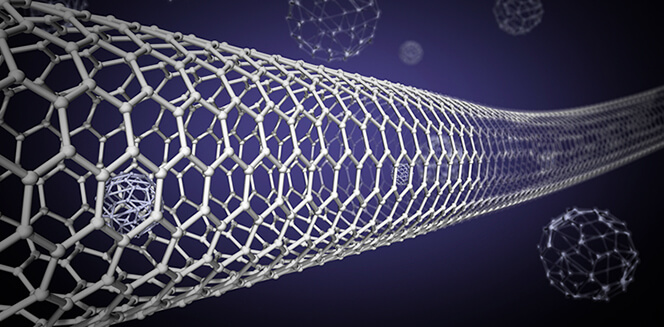

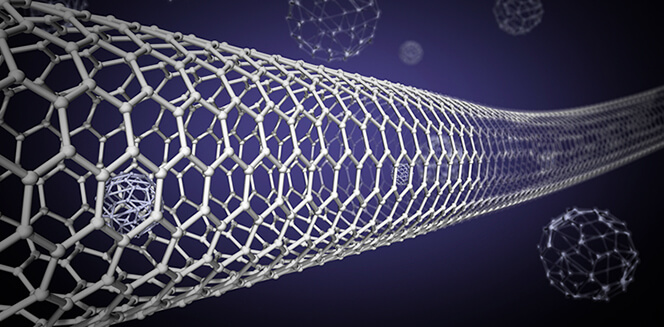

The Rise of IoT Security

The proliferation of Internet of Things (IoT) devices in manufacturing presents new security challenges. Manufacturers prioritize cybersecurity by investing in:

- Secure IoT protocols: Using secure protocols to communicate with IoT devices is crucial.

- IoT device management: Centralized management of IoT devices allows for better security control.

- Regular firmware updates: Keeping IoT device firmware updated is essential to patching vulnerabilities.

Increased Collaboration and Information Sharing

Collaboration is key to improving manufacturing cybersecurity. This includes:

- Collaboration between manufacturers and cybersecurity experts: Sharing information and best practices.

- Industry-specific cybersecurity standards and best practices: Adopting these standards helps improve overall security.

- Information sharing initiatives: Participating in industry groups that share threat intelligence.

Conclusion

The 41% increase in cybersecurity investment by manufacturers underscores the critical importance of prioritizing cybersecurity in the manufacturing sector. The rising frequency and sophistication of cyberattacks, coupled with the unique vulnerabilities of ICS and legacy systems, necessitate a proactive and comprehensive approach to security. Manufacturers are investing in improved network security, enhanced endpoint security, employee training, and cybersecurity professionals to protect their operations. Future trends, including AI-driven security solutions and secure IoT management, will further shape manufacturing cybersecurity strategies. Don't let your manufacturing business become the next victim. Prioritize cybersecurity today and secure your future. Learn more about effective manufacturers' cybersecurity strategies.

Featured Posts

-

Cassie Ventura And Alex Fines Red Carpet Appearance Photos From The Mob Land Premiere

May 13, 2025

Cassie Ventura And Alex Fines Red Carpet Appearance Photos From The Mob Land Premiere

May 13, 2025 -

Catch Up On All The Efl Highlights Goals Saves And More

May 13, 2025

Catch Up On All The Efl Highlights Goals Saves And More

May 13, 2025 -

Sicherheitsalarm An Braunschweiger Schule Kinder In Sicherheit

May 13, 2025

Sicherheitsalarm An Braunschweiger Schule Kinder In Sicherheit

May 13, 2025 -

Mlb Home Run Prop Bets Today April 26th Tuckers Hr And More

May 13, 2025

Mlb Home Run Prop Bets Today April 26th Tuckers Hr And More

May 13, 2025 -

Nhl Draft Lottery Live Studio Drawing Adds New Twist

May 13, 2025

Nhl Draft Lottery Live Studio Drawing Adds New Twist

May 13, 2025

Latest Posts

-

Tempah Byd Ev Di Mas 2025 And Dapatkan Kredit Cas Rm 800 9 15 Mei Nikmati Konsert Rentak Elektrik

May 13, 2025

Tempah Byd Ev Di Mas 2025 And Dapatkan Kredit Cas Rm 800 9 15 Mei Nikmati Konsert Rentak Elektrik

May 13, 2025 -

Complete Byd Seal Buying Guide Specs Price And More

May 13, 2025

Complete Byd Seal Buying Guide Specs Price And More

May 13, 2025 -

Byd Seal The Ultimate Buyers Guide For 2024

May 13, 2025

Byd Seal The Ultimate Buyers Guide For 2024

May 13, 2025 -

Byd Seal Buyers Guide A Comprehensive Review

May 13, 2025

Byd Seal Buyers Guide A Comprehensive Review

May 13, 2025 -

Addendum Analyzing Byds Success In The Ev Battery Market

May 13, 2025

Addendum Analyzing Byds Success In The Ev Battery Market

May 13, 2025