Manufacturing Jobs In America: A Post-Trump Assessment

Table of Contents

The Trump Administration's Impact on Manufacturing

The Trump administration implemented several policies aimed at boosting American manufacturing, with mixed results.

Tariffs and Trade Wars

The administration's strategy of imposing tariffs on imported goods, particularly steel and aluminum, aimed to protect domestic manufacturers and increase American manufacturing jobs. However, the impact was complex and far-reaching.

- Increased costs for businesses: Tariffs raised the prices of imported materials, increasing production costs for many American businesses.

- Retaliatory tariffs from other countries: Other nations responded with their own tariffs, impacting American exports and harming industries like agriculture.

- Impact on specific industries: While some sectors like steel experienced short-term gains, others, such as automotive manufacturing and agriculture, faced significant challenges due to increased input costs and reduced export markets.

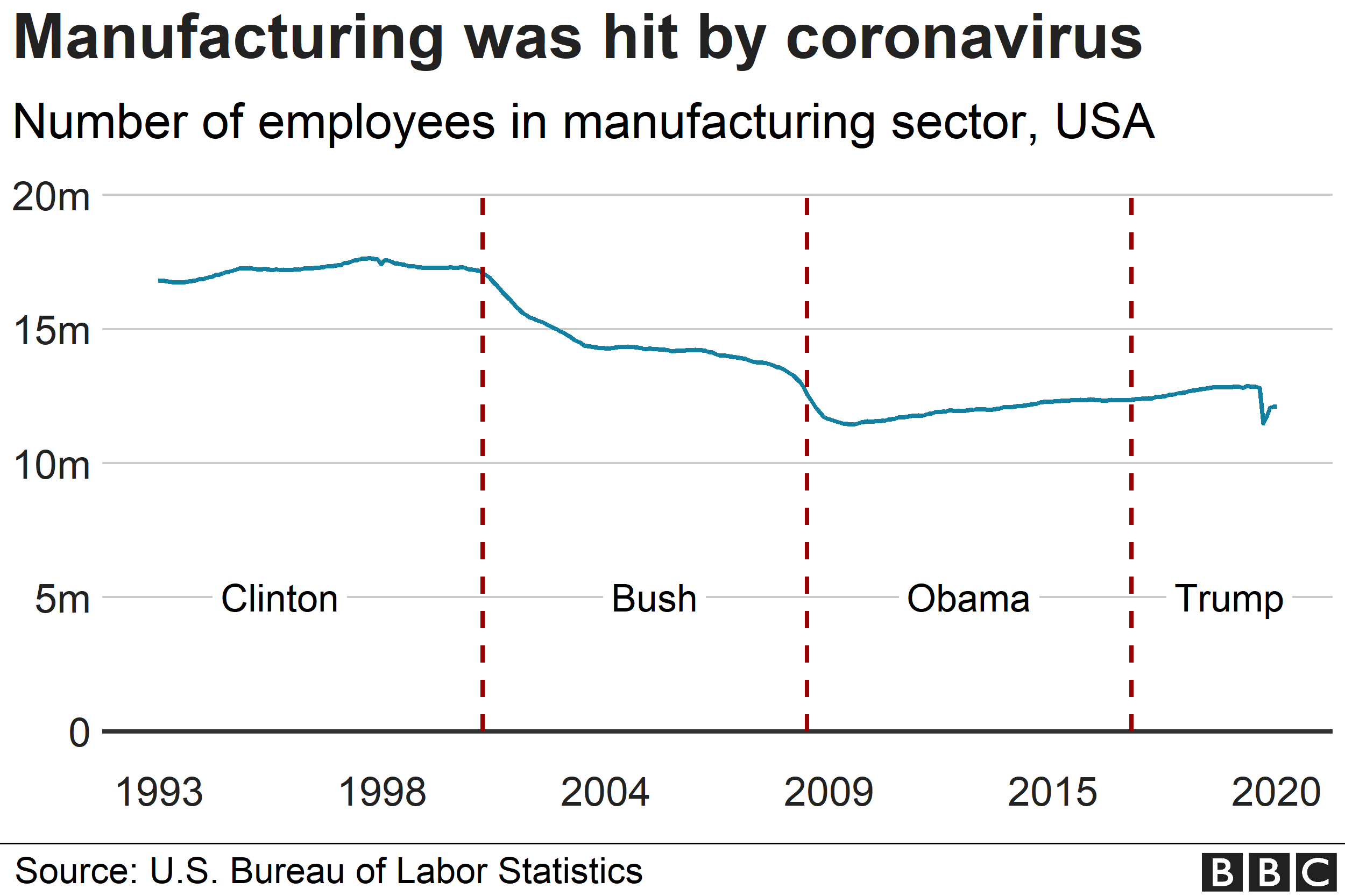

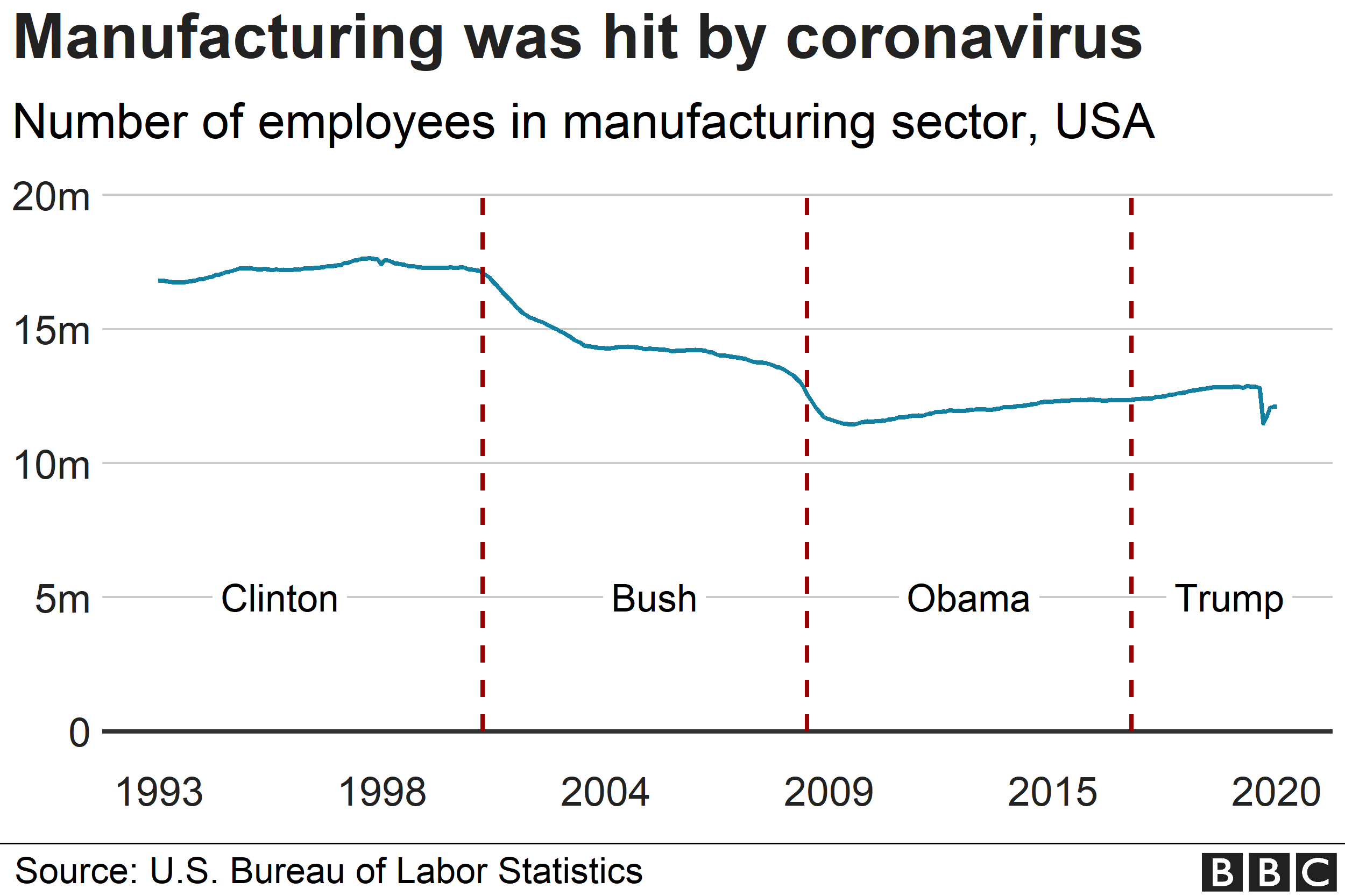

- Job creation claims vs. reality: While the administration claimed significant job creation, independent analyses suggest the net impact on manufacturing employment was far less dramatic, with job growth often attributed to pre-existing trends rather than tariff policies. Data from the Bureau of Labor Statistics paints a more nuanced picture than initial claims.

Regulatory Changes

Deregulation was another key component of the Trump administration's manufacturing policy. The impact of these changes on manufacturing employment is a subject of ongoing debate.

- Environmental regulations: Relaxing environmental regulations potentially lowered compliance costs for some manufacturers, but also raised concerns about environmental damage and long-term sustainability.

- Labor regulations: Changes to labor laws may have reduced some costs for businesses but also sparked debates about worker safety and fair labor practices.

- Pros and cons of deregulation: While deregulation might have offered short-term cost savings, the long-term effects on worker safety, environmental protection, and overall competitiveness remain to be fully assessed. The impact on job creation is particularly complex and difficult to isolate from other economic factors.

The Current State of Manufacturing Jobs in America

Understanding the current landscape of manufacturing jobs requires a sector-by-sector analysis.

Job Growth and Decline by Sector

The manufacturing sector isn't monolithic. Growth in some areas contrasts sharply with decline in others.

- Sectors experiencing growth: Pharmaceuticals, technology-related manufacturing, and certain specialized sectors have seen job growth, driven by innovation and technological advancements.

- Sectors experiencing decline: Traditional manufacturing sectors like textiles and some segments of the automotive industry have faced challenges from automation, global competition, and changing consumer demands.

- Regional variations in job growth: Job growth in manufacturing is not evenly distributed geographically. Certain states and regions benefit more than others, often reflecting existing infrastructure, skillsets, and industry clusters. [Insert chart/graph visualizing job creation/loss data from BLS here].

Automation and the Future of Work

Automation is a transformative force reshaping the manufacturing landscape.

- Job displacement due to automation: Robotics and AI-driven automation are displacing some manufacturing jobs, particularly those involving repetitive tasks.

- The need for reskilling and upskilling: To adapt to this changing environment, the workforce requires significant reskilling and upskilling initiatives to acquire new skills in areas like robotics, programming, and data analysis.

- The potential for new job creation: While some jobs are lost, automation also creates new opportunities in areas such as engineering, software development, and maintenance of automated systems. The emergence of AI and machine learning in manufacturing generates further demand for skilled specialists.

Challenges and Opportunities for the Future of American Manufacturing

To ensure the future competitiveness of American manufacturing, several key challenges must be addressed.

Infrastructure and Investment

Modern, efficient infrastructure is crucial for manufacturing growth.

- The role of government investment: Significant investment in roads, bridges, broadband internet access, and other infrastructure is vital to support efficient transportation, communication, and supply chains.

- Private sector investment: Encouraging private sector investment in manufacturing infrastructure is also critical for sustainable growth.

- The need for long-term strategic planning: A long-term strategic approach to infrastructure development is necessary to ensure that investments align with the evolving needs of the manufacturing sector.

Workforce Development and Education

Addressing the skills gap is essential.

- The importance of vocational training: Expanding access to high-quality vocational training programs is crucial for equipping workers with the skills needed in modern manufacturing.

- Apprenticeships and STEM education: Apprenticeships and robust STEM (Science, Technology, Engineering, and Mathematics) education from primary school onward are key to developing a future-ready workforce.

- Initiatives aimed at improving workforce development: Government and private sector initiatives focused on workforce development, including apprenticeships, retraining programs, and scholarships, are needed to close the skills gap.

Global Competition and Supply Chain Resilience

Improving competitiveness and building resilient supply chains are paramount.

- Reshoring and nearshoring: Strategies such as reshoring (bringing manufacturing back to the US) and nearshoring (moving production to nearby countries) can reduce reliance on distant supply chains and enhance security.

- Diversification of supply chains: Diversifying supply chains to reduce vulnerability to disruptions is critical for ensuring the stability of American manufacturing.

- The role of government policy: Targeted government policies can incentivize reshoring, nearshoring, and supply chain diversification, fostering a more resilient and competitive manufacturing sector.

Conclusion

The state of manufacturing jobs in America post-Trump is complex. While some policies aimed to boost the sector, the reality is more nuanced, influenced by global trade dynamics, automation, and pre-existing economic trends. Challenges remain, particularly in infrastructure development, workforce development, and navigating global competition. However, substantial opportunities also exist for growth through innovation, automation, and strategic investments in education and infrastructure. The future of American manufacturing hinges on proactive policymaking, private sector engagement, and a commitment to upskilling and reskilling the workforce. The future of American manufacturing and its workforce depends on informed action; let's work together to build a robust and sustainable manufacturing sector in America. Learn more about initiatives supporting manufacturing jobs in America and advocate for policies that strengthen this vital part of our economy.

Featured Posts

-

Clean Energy Under Siege A Growing Threat To A Booming Industry

May 21, 2025

Clean Energy Under Siege A Growing Threat To A Booming Industry

May 21, 2025 -

The Trump Presidency And The Surge In American Applications For European Citizenship

May 21, 2025

The Trump Presidency And The Surge In American Applications For European Citizenship

May 21, 2025 -

Huizenprijzen Stijgen Volgens Abn Amro Wat Betekent Dit Voor Jou

May 21, 2025

Huizenprijzen Stijgen Volgens Abn Amro Wat Betekent Dit Voor Jou

May 21, 2025 -

Navy Ethics Scandal Bribery Charges Against Retired Admiral

May 21, 2025

Navy Ethics Scandal Bribery Charges Against Retired Admiral

May 21, 2025 -

Problemen Met Online Betalingen Bij Abn Amro Opslag

May 21, 2025

Problemen Met Online Betalingen Bij Abn Amro Opslag

May 21, 2025

Latest Posts

-

Suomi Ryhmaen Avauskokoonpanossa Muutoksia Kaellmanin Paikka Kyseenalainen

May 21, 2025

Suomi Ryhmaen Avauskokoonpanossa Muutoksia Kaellmanin Paikka Kyseenalainen

May 21, 2025 -

Huuhkajien Avauskokoonpano Naein Muuttuu Suomi Ryhmae

May 21, 2025

Huuhkajien Avauskokoonpano Naein Muuttuu Suomi Ryhmae

May 21, 2025 -

Kolme Muutosta Huuhkajien Avauskokoonpanoon Benjamin Kaellman Penkillae

May 21, 2025

Kolme Muutosta Huuhkajien Avauskokoonpanoon Benjamin Kaellman Penkillae

May 21, 2025 -

Huuhkajat Avauskokoonpanoon Merkittaeviae Muutoksia Kaellman Ulos

May 21, 2025

Huuhkajat Avauskokoonpanoon Merkittaeviae Muutoksia Kaellman Ulos

May 21, 2025 -

Huuhkajien Avauskokoonpano Yllaetyksiae Ja Muutoksia

May 21, 2025

Huuhkajien Avauskokoonpano Yllaetyksiae Ja Muutoksia

May 21, 2025