Meet The Cricket Bat Master: Preserving A Legacy

Table of Contents

The Art and Science of Cricket Bat Making

Creating a high-performance cricket bat is a complex process, a delicate dance between artistry and scientific precision. Every stage, from selecting the raw material to the final finishing touches, demands skill, experience, and a deep understanding of the game itself.

Selecting the Perfect Willow

The journey begins with the selection of the raw material – English willow. Not just any willow will do; the finest bats are crafted from Grade 1 English willow, renowned for its exceptionally close grain and high density. These characteristics are crucial for delivering power, durability, and the coveted "sweet spot" that every batsman craves.

- Different grades of willow: Grade 1 willow boasts the closest grain and highest density, resulting in superior performance. Lower grades, while still usable, offer less power and durability.

- Impact on bat performance: The density and grain directly influence the bat's ability to transfer energy to the ball, impacting hitting power and distance.

- Sourcing sustainable willow: Ethical and sustainable sourcing of willow is paramount to ensuring the long-term viability of the craft. Many master bat makers prioritize responsible forestry practices.

Shaping the Blade

Once the perfect piece of willow is selected, the meticulous process of shaping the blade begins. This involves using specialized tools and techniques passed down through generations. The master craftsman carefully removes layers of wood, gradually revealing the bat's final form. This is not simply woodworking; it's sculpting, an artistic process that demands precision and an intuitive understanding of wood's properties.

- Different shaping techniques: Traditional methods often involve hand tools, while some modern workshops incorporate computer-aided design (CAD) for precise shaping.

- The role of skilled craftsmanship: The craftsman's expertise is crucial in creating a balanced bat with optimal weight distribution and a well-defined sweet spot.

- Creating the sweet spot: The sweet spot is the area on the blade where the impact feels most comfortable and transmits maximum energy to the ball. Creating this is a hallmark of a skilled bat maker.

The Handle's Significance

The handle is often overlooked, yet it plays a crucial role in a batsman's performance. The handle, typically made from cane, provides the connection between the batsman and the bat. The grip, usually made from rubber or leather, further enhances control and comfort. The choice of handle type, size, and grip significantly impacts the batsman's feel and control.

- Different handle types: Various handle materials and constructions exist, each offering a unique feel and performance characteristic.

- The importance of grip size and comfort: A comfortable grip is essential for prolonged use and prevents fatigue. The right size ensures control and prevents slippage.

- The role of handle design in performance: A well-designed handle contributes to balance, swing, and overall bat performance.

Passing the Torch: Mentorship and Training

The art of cricket bat making is more than just a profession; it's a legacy passed down through generations. Preserving this craft requires a commitment to mentorship and training, ensuring that the skills and knowledge are not lost to time.

Apprentice Programs and Knowledge Transfer

Traditionally, cricket bat making has relied on an apprenticeship model, where aspiring craftsmen learn the trade under the guidance of experienced masters. This hands-on training ensures the meticulous techniques and secrets of the craft are passed down faithfully.

- Challenges in finding new apprentices: The demanding nature of the work and the long training period can present challenges in attracting new apprentices.

- The importance of formal and informal training methods: A combination of formal apprenticeships and informal learning through observation and practice is ideal.

- The role of family traditions: In many cases, the craft is passed down within families, creating a unique lineage of skilled bat makers.

Modernizing the Craft While Preserving Tradition

The challenge lies in balancing the preservation of traditional methods with the integration of modern techniques and technologies. Modern tools can improve efficiency without compromising the quality or craftsmanship.

- Using modern tools while maintaining craftsmanship: CAD design and CNC machines can assist with precise shaping, while hand-finishing ensures the unique quality of the handcrafted bat.

- Balancing tradition with efficiency: Modern technologies can help streamline the production process without sacrificing the traditional craftsmanship inherent in the best cricket bats.

- Adapting to changing player demands: Modern batsmen have specific requirements, and bat makers must adapt to these evolving needs while maintaining the integrity of the craft.

The Future of Cricket Bat Making: Challenges and Opportunities

The future of cricket bat making presents both significant challenges and exciting opportunities. The industry faces increasing competition from mass-produced bats, but the inherent value of handcrafted bats remains strong.

Competition from Mass Production

Mass-produced bats offer a lower price point, posing a challenge to artisan bat makers. However, handcrafted bats offer superior quality, performance, and a unique story that appeals to discerning customers.

- The value proposition of handcrafted bats: Handcrafted bats provide superior quality, performance, and a unique connection to tradition that mass-produced bats cannot replicate.

- Marketing and branding strategies: Effective marketing is key to highlighting the value and craftsmanship of handmade cricket bats and reaching a wider audience.

- Reaching new markets: Expanding into new markets and reaching new customer segments can help diversify revenue streams for artisan bat makers.

Sustainability and Ethical Sourcing

Environmental responsibility and ethical sourcing are becoming increasingly important considerations for consumers. Sustainable forestry practices and ethical labor practices are essential for the long-term sustainability of the craft.

- Sustainable forestry practices: Using sustainably sourced willow ensures the availability of high-quality materials for future generations.

- Using eco-friendly materials: Minimizing environmental impact requires careful consideration of all materials used in the bat-making process.

- Promoting ethical labor practices: Fair wages and safe working conditions are paramount in ensuring the ethical production of handcrafted cricket bats.

Preserving the Legacy Through Documentation and Education

Documenting the techniques, processes, and history of cricket bat making is crucial for its preservation. Initiatives that educate the public and train new craftsmen will ensure the craft thrives for years to come.

- Creating educational materials: Books, videos, and online resources can help preserve knowledge and share the craft with a wider audience.

- Establishing museums or workshops: Dedicated spaces can showcase the history and techniques of cricket bat making, inspiring future generations.

- Digital preservation of knowledge: Archiving videos, images, and detailed descriptions of the techniques can ensure the craft's survival, even in a digital age.

Securing the Future of Cricket Bat Mastery

The future of cricket bat making hinges on addressing the challenges and capitalizing on the opportunities discussed. The craft faces competition from mass production, but the unique value and quality of handcrafted bats remain unmatched. Sustainability and ethical sourcing are vital for ensuring the long-term viability of the industry. By documenting the craft and training new artisans, we can collectively safeguard this rich heritage. Let's collectively work to preserve the legacy of the cricket bat master, ensuring this exquisite craft continues to thrive for generations to come. Discover the artistry of handcrafted cricket bats and support the masters who create them.

Featured Posts

-

Colours Of Time Cedric Klapisch Film Sold By Studiocanal At Cannes

May 23, 2025

Colours Of Time Cedric Klapisch Film Sold By Studiocanal At Cannes

May 23, 2025 -

Discover Cambridge And Somerville Viva Central Hot Sauce Festival And Open Studios This Week

May 23, 2025

Discover Cambridge And Somerville Viva Central Hot Sauce Festival And Open Studios This Week

May 23, 2025 -

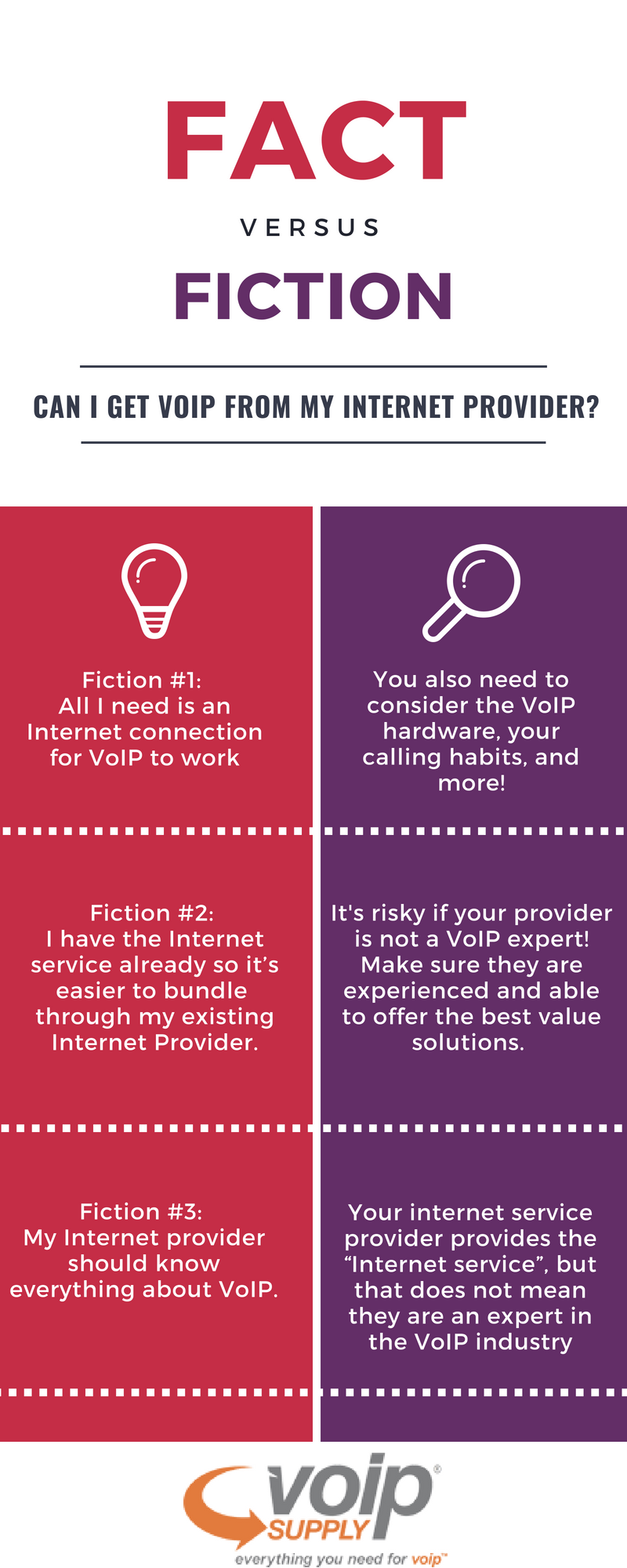

The Whos Band Name Fact Vs Fiction

May 23, 2025

The Whos Band Name Fact Vs Fiction

May 23, 2025 -

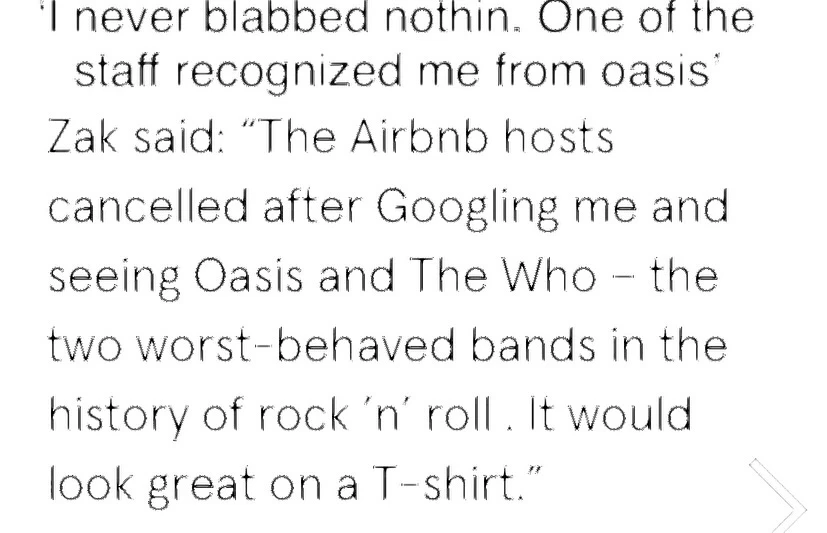

The Whos Zak Starkey Addressing Departure Rumors

May 23, 2025

The Whos Zak Starkey Addressing Departure Rumors

May 23, 2025 -

Hulu Movie Departures Everything Leaving In Month Year

May 23, 2025

Hulu Movie Departures Everything Leaving In Month Year

May 23, 2025

Latest Posts

-

Analyzing Succession Character Development And Plot Twists On Sky Atlantic Hd

May 23, 2025

Analyzing Succession Character Development And Plot Twists On Sky Atlantic Hd

May 23, 2025 -

Kieran Culkin To Play Caesar Flickerman In The Hunger Games Prequel

May 23, 2025

Kieran Culkin To Play Caesar Flickerman In The Hunger Games Prequel

May 23, 2025 -

Succession On Sky Atlantic Hd Power Family And Betrayal

May 23, 2025

Succession On Sky Atlantic Hd Power Family And Betrayal

May 23, 2025 -

Sunrise On The Reaping Kieran Culkin Cast As Caesar Flickerman

May 23, 2025

Sunrise On The Reaping Kieran Culkin Cast As Caesar Flickerman

May 23, 2025 -

Fact Check Separating Fact From Fiction Suraj Venjaramoodu And The Kieran Culkin Oscar Speech

May 23, 2025

Fact Check Separating Fact From Fiction Suraj Venjaramoodu And The Kieran Culkin Oscar Speech

May 23, 2025