Solving OEM Supply Chain Issues: SG Wireless' Enhanced Manufacturing Approach

Table of Contents

Proactive Component Sourcing and Inventory Management

Proactive sourcing is the cornerstone of our strategy for mitigating OEM supply chain issues. This involves more than simply ordering parts when needed; it's about securing components well in advance of production needs, building resilient relationships with key suppliers, and strategically diversifying our sourcing to avoid single-point failures. Unexpected disruptions, whether due to geopolitical instability, natural disasters, or supplier insolvency, can cripple production. By anticipating potential problems and securing our supply chain proactively, we shield our OEM partners from these risks.

Our inventory management strategies are equally crucial. We employ a blend of Just-in-Time (JIT) inventory management for frequently used, readily available components and strategic safety stock for critical components with longer lead times or higher risk of disruption. Utilizing advanced inventory management software, we optimize stock levels, minimizing waste while ensuring we have the necessary parts on hand to meet production demands.

- Diversified supplier base to mitigate risk from relying on a single source.

- Long-term contracts to secure stable pricing and predictable supply.

- Advanced forecasting models leveraging machine learning to predict demand fluctuations accurately.

- Real-time inventory tracking and management using cutting-edge software for enhanced visibility and control.

Flexible and Agile Manufacturing Processes

Addressing OEM supply chain issues also requires adaptability. SG Wireless utilizes flexible and agile manufacturing processes, enabling us to quickly adapt to changing demands and incorporate design modifications without significant delays or disruptions. This flexibility is achieved through a combination of advanced technologies and lean manufacturing principles.

Our agile manufacturing practices emphasize collaboration, both internally and with our OEM partners. We foster a culture of rapid response to market changes and continuous improvement, constantly seeking ways to optimize our manufacturing flow and reduce lead times. This proactive approach to problem-solving is essential in navigating the complexities of the global supply chain.

- Modular design for easy customization and upgrades, allowing for quicker adaptation to evolving specifications.

- Lean manufacturing principles to minimize waste, maximize efficiency, and optimize resource utilization.

- Quick changeover capabilities enabling us to seamlessly transition between different product lines, maximizing throughput.

- Automated production lines for greater speed, precision, and reduced human error, improving overall quality and efficiency.

State-of-the-Art Technology Integration

Our commitment to solving OEM supply chain issues extends to the integration of state-of-the-art technology. Automation and data analytics are integral to our enhanced manufacturing approach. Robotic process automation streamlines repetitive tasks, increasing efficiency and reducing human error. Data-driven decision-making, informed by real-time data analytics, enables us to optimize processes, predict potential bottlenecks, and proactively address challenges before they impact production. Predictive maintenance, using sensor data and machine learning algorithms, helps us minimize downtime by anticipating and preventing equipment failures.

Technology also significantly improves quality control. Automated inspection systems and advanced quality control measures ensure consistent product quality and reduce defects, ultimately delivering higher-quality products to our OEM partners.

- Real-time data analytics for improved decision-making, enabling proactive adjustments to production processes.

- Automated quality control processes minimizing defects and ensuring consistent product quality.

- Predictive maintenance using IoT sensors and AI to prevent equipment failures and minimize downtime.

- Advanced testing and validation procedures to ensure products meet the highest quality standards.

Transparent and Collaborative Communication

Open and transparent communication is paramount in addressing OEM supply chain issues. At SG Wireless, we believe that strong, collaborative relationships are crucial for a successful partnership. We provide proactive updates, clear reporting, and engage in shared decision-making throughout the manufacturing process. This keeps our OEM partners informed and involved, fostering trust and confidence.

We understand that effective communication strengthens the entire supply chain. By maintaining strong supplier relationships and fostering transparent communication with our partners, we build a resilient network capable of navigating unforeseen challenges together. Dedicated account managers provide personalized support, ensuring quick response times and effective problem-solving.

- Regular progress reports and updates to keep OEM partners fully informed.

- Dedicated account managers for personalized support and proactive communication.

- Collaborative problem-solving to address challenges promptly and effectively.

- Open communication channels for quick issue resolution and seamless information flow.

Conclusion

SG Wireless effectively addresses persistent OEM supply chain issues by implementing a comprehensive strategy that encompasses proactive sourcing, flexible manufacturing, advanced technology integration, and transparent communication. Our enhanced approach ensures reliable delivery, consistent quality, and cost-effective solutions for our OEM partners. By partnering with SG Wireless, you can overcome the challenges of the global supply chain and focus on your core business objectives. Contact us today to learn more about how our solutions can help you solve your OEM supply chain issues and achieve manufacturing excellence.

Featured Posts

-

Mzahrat Hashdt Btl Abyb Ttalb Bitlaq Srah Alasra

May 26, 2025

Mzahrat Hashdt Btl Abyb Ttalb Bitlaq Srah Alasra

May 26, 2025 -

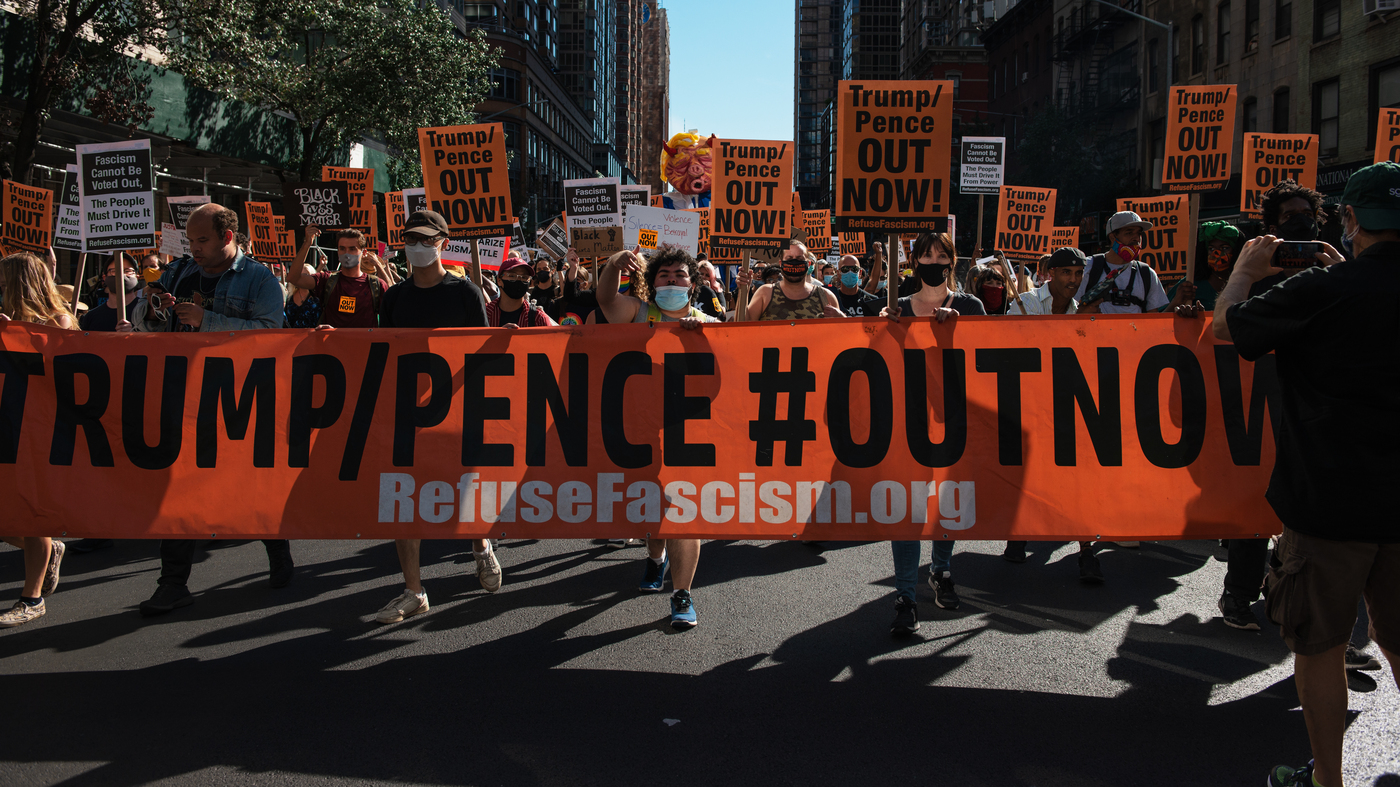

Is Fascism Rising Delaware Governors Concerns Following The Biden And Trump Eras

May 26, 2025

Is Fascism Rising Delaware Governors Concerns Following The Biden And Trump Eras

May 26, 2025 -

Freed Hostages Berger And Weiss To Participate In March Of The Living

May 26, 2025

Freed Hostages Berger And Weiss To Participate In March Of The Living

May 26, 2025 -

Van Der Poel Third At Paris Roubaix Pogacar A Minute Behind

May 26, 2025

Van Der Poel Third At Paris Roubaix Pogacar A Minute Behind

May 26, 2025 -

Jadwal And Lokasi Moto Gp Inggris 2025 Panduan Lengkap Penonton

May 26, 2025

Jadwal And Lokasi Moto Gp Inggris 2025 Panduan Lengkap Penonton

May 26, 2025

Latest Posts

-

Pogacars Dominant Solo Victory At The Tour Of Flanders

May 26, 2025

Pogacars Dominant Solo Victory At The Tour Of Flanders

May 26, 2025 -

Unstoppable Pogacar Claims Tour Of Flanders

May 26, 2025

Unstoppable Pogacar Claims Tour Of Flanders

May 26, 2025 -

Pogacars Powerful Performance Secures Tour Of Flanders

May 26, 2025

Pogacars Powerful Performance Secures Tour Of Flanders

May 26, 2025 -

Tour Of Flanders 2024 Pogacars Stunning Solo

May 26, 2025

Tour Of Flanders 2024 Pogacars Stunning Solo

May 26, 2025 -

Pogacar Solos To Tour Of Flanders Win

May 26, 2025

Pogacar Solos To Tour Of Flanders Win

May 26, 2025