Steel Industry Decarbonization: The Impact Of Eramet's EraLow

Table of Contents

Understanding Eramet's eraLow Process

Eramet's eraLow process represents a significant leap forward in low-carbon steelmaking. Unlike traditional blast furnace methods that rely heavily on coking coal, eraLow utilizes a direct reduction process, significantly reducing reliance on fossil fuels. This innovative approach centers around using hydrogen and other renewable energy sources to reduce iron ore, resulting in a substantially lower carbon intensity steel production process.

- Key technologies used in eraLow: Direct reduction technology, hydrogen production from renewable sources, optimized energy management systems, and potentially carbon capture and storage (CCS) integration in future iterations.

- Comparison to traditional steelmaking processes: Traditional blast furnaces generate significant CO2 emissions primarily from the combustion of coking coal. Eramet's eraLow process drastically reduces this, offering a pathway towards near-zero emission steel production.

- Patents and unique aspects: Eramet holds key patents related to specific aspects of the eraLow process, protecting its innovative technology and ensuring a competitive advantage in the market.

Reduction in CO2 Emissions

Eramet's eraLow process boasts a substantial reduction in CO2 emissions compared to traditional steelmaking methods. While precise figures depend on the specific energy mix used, independent studies suggest a potential reduction of up to 90% in CO2 emissions.

- Percentage reduction: Initial estimations point towards a significant reduction ranging from 70% to over 90%, depending on factors such as hydrogen source and energy mix.

- Independent verification and certifications: Eramet is actively working towards securing independent verification and relevant certifications to validate the environmental performance claims of its eraLow process.

- Potential for further emission reductions: Future improvements, such as integrating CCS technology and further optimizing the hydrogen production process, hold the potential for even greater emission reductions, paving the way for near-zero-emission steel.

Economic Viability of eraLow

The economic viability of eraLow is a critical aspect of its widespread adoption. While the initial investment in new infrastructure may be higher than upgrading traditional facilities, the long-term cost-effectiveness is highly promising.

- Cost comparison with traditional methods: While initial capital expenditures may be higher, the reduced operating costs associated with lower energy consumption and decreased raw material costs can lead to long-term cost savings. A detailed lifecycle cost analysis is crucial for accurate comparison.

- Potential for cost reduction over time: Scaling up production and optimizing the eraLow process through continuous improvement initiatives will likely lead to further cost reductions over time, making it increasingly competitive with traditional methods.

- Government incentives and subsidies: Government support through incentives, subsidies, and carbon pricing mechanisms can play a significant role in accelerating the adoption of eraLow and other decarbonization technologies in the steel industry.

Environmental Impact Beyond CO2 Reduction

The environmental benefits of eraLow extend beyond CO2 emission reductions. The process demonstrates a commitment to a more sustainable and responsible approach to steel production.

- Reduced water consumption: The eraLow process is designed to minimize water usage compared to traditional methods, contributing to water resource conservation.

- Minimized waste generation: The innovative process aims to reduce waste generation throughout the production lifecycle, leading to a smaller environmental footprint.

- Potential for using recycled materials: The eraLow process offers potential for integrating higher proportions of recycled materials into steel production, further reducing reliance on virgin resources and minimizing environmental impact.

Challenges and Future Outlook for eraLow

Despite its considerable promise, the widespread adoption of eraLow faces several challenges. Addressing these challenges is crucial for realizing the full potential of this transformative technology.

- Scaling up production: Scaling up production to meet the massive industrial demand for steel requires significant investment in infrastructure and technology.

- Integration with existing steel production infrastructure: Integrating eraLow into existing steel mills requires careful planning and potential modifications to existing infrastructure.

- Collaboration with other industry players: Collaboration with steel producers, equipment manufacturers, and research institutions is essential for driving the widespread adoption of eraLow.

- Future research and development: Ongoing research and development are crucial to further optimize the process, reduce costs, and enhance its environmental performance.

Conclusion

Eramet's eraLow presents a significant advancement in steel industry decarbonization. Its innovative approach promises substantial reductions in CO2 emissions, along with broader environmental and economic benefits. While challenges remain, the potential of eraLow to reshape the future of steel production is undeniable. Its ability to reduce the carbon footprint of one of the world's most emission-intensive industries is a significant step towards a greener future.

Call to Action: Learn more about Eramet's eraLow and its potential to revolutionize sustainable steel production. Explore the possibilities of implementing this groundbreaking technology for a greener future. Discover how Eramet's eraLow can contribute to your company's sustainability goals and help you achieve your net-zero targets. Contact Eramet today to discuss how eraLow can benefit your operations.

Featured Posts

-

Tommy Fury Challenges Jake Paul To A Rematch What Happened

May 14, 2025

Tommy Fury Challenges Jake Paul To A Rematch What Happened

May 14, 2025 -

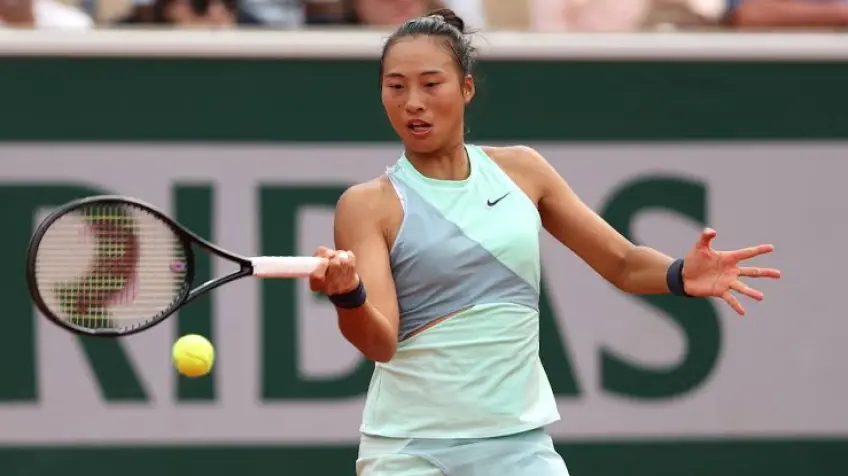

Potapova Upsets Zheng Qinwen At Madrid Open

May 14, 2025

Potapova Upsets Zheng Qinwen At Madrid Open

May 14, 2025 -

Mission Impossible Dead Reckoning Part Two Trailer Release Date Announced

May 14, 2025

Mission Impossible Dead Reckoning Part Two Trailer Release Date Announced

May 14, 2025 -

Nonna Meet The Cast And Their Characters

May 14, 2025

Nonna Meet The Cast And Their Characters

May 14, 2025 -

Alqfzt Alkbra Ywrwfyjn Wsylyn Dywn

May 14, 2025

Alqfzt Alkbra Ywrwfyjn Wsylyn Dywn

May 14, 2025