The US Army And Right-to-Repair: Benefits, Challenges, And The Future Of Military Technology

Table of Contents

Benefits of Implementing Right-to-Repair in the US Army

Implementing right-to-repair initiatives within the US Army could yield substantial advantages across various operational and financial aspects.

Reduced Maintenance Costs

The current system of relying heavily on Original Equipment Manufacturers (OEMs) for repairs is expensive and often inefficient. A right-to-repair approach offers a pathway to significantly lower maintenance costs.

- Lower reliance on Original Equipment Manufacturers (OEMs): By allowing independent repair shops and even trained soldiers to perform repairs, the Army can reduce its dependence on often overpriced OEM services.

- Reduced downtime: Faster repair times translate directly into increased equipment availability and operational readiness.

- Increased lifespan of equipment through timely repairs: Preventative maintenance and quicker repairs can extend the service life of military equipment, reducing the need for frequent replacements.

- Training opportunities for soldiers in maintenance and repair skills: Empowering soldiers with repair skills enhances their versatility and reduces reliance on specialized contractors.

- Potential for cost savings through the use of third-party repair services: Competition among repair providers can drive down prices and improve service quality.

For example, consider the cost of repairing a damaged Humvee engine. OEM repair can easily cost tens of thousands of dollars, while a well-trained mechanic using readily available parts might complete the same repair for a fraction of the price. This cost saving scales dramatically across the vast inventory of military equipment.

Enhanced Operational Readiness

Right-to-repair directly impacts operational readiness by enabling faster repair cycles and improved equipment availability.

- Faster repair times: Quick repairs mean quicker return to operational status, crucial in time-sensitive military operations.

- Increased availability of equipment: Reduced downtime leads to a larger pool of functional equipment, improving overall readiness.

- Reduced reliance on external contractors: Internal repair capabilities strengthen the Army's self-sufficiency and reduce dependence on external contractors, particularly valuable in remote or contested environments.

- Improved logistical efficiency: Decentralized repair capabilities streamline logistics, reducing the need for extensive transportation of equipment to centralized repair facilities.

- Decentralized repair capabilities improve resilience in field operations: Soldiers can perform basic repairs on the front lines, minimizing delays and enhancing operational flexibility.

Imagine a scenario where a critical communication system malfunctions in a remote deployment. With right-to-repair, soldiers with appropriate training might be able to troubleshoot and fix the issue on-site, minimizing communication downtime and avoiding the lengthy delays associated with waiting for external support.

Fostering Innovation and Competition

Opening the repair market fosters a competitive environment that drives innovation and improves the quality of repair services.

- Encourages development of innovative repair tools and techniques: A more open market encourages the development of specialized tools and techniques tailored to military equipment.

- Creates a more competitive market for repair services: Competition among repair providers leads to better pricing, improved service quality, and faster turnaround times.

- Promotes the emergence of specialized repair expertise: Independent repair shops can develop specialized expertise in repairing specific types of military equipment.

- Drives down the cost of spare parts and components: Increased competition in the supply of spare parts can lead to lower prices for the Army.

- Leads to better quality control in repairs: The competitive landscape motivates repair providers to maintain high quality standards to attract and retain customers.

By allowing smaller businesses to compete in the military repair market, the Army can benefit from specialized knowledge and potentially more cost-effective solutions.

Challenges Associated with Right-to-Repair in the Military Context

Despite the potential benefits, significant challenges must be addressed before implementing a comprehensive right-to-repair policy within the US Army.

Security Concerns

Security is paramount in military operations, and right-to-repair introduces potential vulnerabilities.

- Risk of unauthorized access to sensitive technology: Providing access to repair manuals and schematics could expose sensitive technologies to unauthorized individuals or adversaries.

- Potential for reverse engineering of military equipment: Third-party access to equipment could facilitate reverse engineering efforts, compromising the Army's technological advantage.

- Concerns regarding the integrity of repairs and the potential for compromised equipment: There's a risk that improperly performed repairs could compromise the functionality and security of equipment.

- Difficulty in verifying the competence of third-party repair providers: Ensuring qualified and trustworthy repair services requires robust verification and certification processes.

- Need for stringent security protocols and oversight: Implementing effective security measures is crucial to mitigate these risks.

Robust security protocols, including strict access controls, background checks for repair personnel, and regular audits, are essential to address these concerns.

Logistical Complications

Implementing a right-to-repair policy across a vast and geographically dispersed organization presents substantial logistical challenges.

- Ensuring access to necessary repair manuals and schematics: Secure distribution of technical documentation is critical, while preventing unauthorized access.

- Maintaining quality control standards across different repair providers: Establishing and enforcing consistent quality control standards is essential to guarantee the reliability of repairs.

- Coordinating repairs across geographically dispersed units: Efficient coordination between geographically dispersed units is essential for effective repair management.

- The complexity of managing a decentralized repair system: Managing a network of decentralized repair capabilities requires sophisticated logistics and inventory management.

- The need for secure supply chains for repair parts and components: Ensuring a reliable supply of authentic parts and components is critical to maintaining equipment integrity.

A robust logistical framework, including a secure parts supply chain and centralized quality control mechanisms, is essential for successful implementation.

Legal and Regulatory Hurdles

Legal and regulatory considerations pose significant obstacles to implementing right-to-repair policies.

- Navigating intellectual property rights: Balancing the right-to-repair with intellectual property rights held by OEMs requires careful legal consideration.

- Compliance with government regulations and contracts: Ensuring compliance with existing regulations and government contracts is crucial.

- Establishing clear liability frameworks: Clear liability frameworks are needed to determine responsibility in case of repair-related failures.

- Addressing concerns regarding warranty provisions: The impact of right-to-repair on warranty provisions needs careful consideration.

- Developing appropriate standards and certifications for repair providers: Establishing standards and certification processes for repair providers is essential for ensuring quality and security.

Careful legal analysis and engagement with relevant stakeholders are needed to address these complexities and ensure a legally sound implementation of right-to-repair policies.

Conclusion

The right-to-repair movement offers substantial potential benefits for the US Army, including reduced costs, improved operational readiness, and increased innovation. However, significant security, logistical, and legal challenges must be addressed before widespread implementation can be considered. A carefully planned and phased approach, incorporating robust security protocols and transparent regulatory frameworks, is crucial to successfully harness the advantages of right-to-repair while mitigating associated risks. The future of military technology hinges on finding a balance between innovation, security, and efficient maintenance. Further research and discussion surrounding right-to-repair are necessary to determine its optimal role in enhancing the effectiveness and readiness of the US Army. Let's continue the conversation on how the right-to-repair movement can contribute to a more efficient and robust US Army.

Featured Posts

-

Amanda Bynes Only Fans A Strict Disclaimer And What To Expect

May 18, 2025

Amanda Bynes Only Fans A Strict Disclaimer And What To Expect

May 18, 2025 -

Taylor Swift And Blake Lively Navigating The It Ends With Us Legal Drama

May 18, 2025

Taylor Swift And Blake Lively Navigating The It Ends With Us Legal Drama

May 18, 2025 -

The Zuckerberg Trump Dynamic Impact On Facebook And Beyond

May 18, 2025

The Zuckerberg Trump Dynamic Impact On Facebook And Beyond

May 18, 2025 -

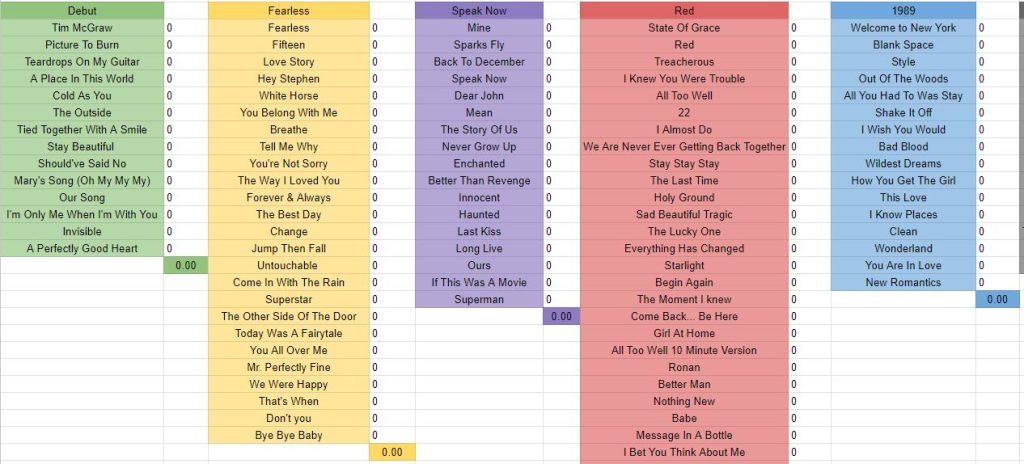

The Ultimate Taylor Swift Album Ranking 11 Albums Reviewed

May 18, 2025

The Ultimate Taylor Swift Album Ranking 11 Albums Reviewed

May 18, 2025 -

Taylor Swifts Lawsuit Against Kanye West Allegations And Implications

May 18, 2025

Taylor Swifts Lawsuit Against Kanye West Allegations And Implications

May 18, 2025

Latest Posts

-

Amanda Bynes Only Fans Debut Photos And Details

May 18, 2025

Amanda Bynes Only Fans Debut Photos And Details

May 18, 2025 -

Amanda Bynes Only Fans What We Know So Far

May 18, 2025

Amanda Bynes Only Fans What We Know So Far

May 18, 2025 -

New Photos Amanda Bynes Post Only Fans Launch

May 18, 2025

New Photos Amanda Bynes Post Only Fans Launch

May 18, 2025 -

Amanda Bynes Only Fans What Fans Can And Can T Expect

May 18, 2025

Amanda Bynes Only Fans What Fans Can And Can T Expect

May 18, 2025 -

Amanda Bynes Steps Out Only Fans Launch And New Photos

May 18, 2025

Amanda Bynes Steps Out Only Fans Launch And New Photos

May 18, 2025