A Cargo Ship's Journey: The Hyundai 650 At The Ulsan Auto Factory

Table of Contents

Embark on a fascinating journey with us as we trace the path of a Hyundai 650 cargo ship, from its departure point to its vital role in transporting crucial automotive components to the bustling Ulsan Auto Factory in South Korea. This article delves into the complexities and importance of maritime logistics in the global automotive industry, focusing specifically on the Hyundai 650's contribution to Hyundai's production prowess. We'll explore the ship itself, the factory it serves, the voyage it undertakes, and the vital role of logistics in this process.

<h2>The Hyundai 650: A Profile of the Vessel</h2>

While the exact specifications of every ship named "Hyundai 650" may vary slightly depending on its build year and modifications, we can create a general profile based on common characteristics of vessels with similar designations within Hyundai's fleet. These are typically large cargo ships designed for efficient and reliable transport of heavy goods, often containers.

-

Size and Capacity: Hyundai 650 class vessels are likely to be substantial, perhaps measuring hundreds of meters in length. Their cargo capacity, expressed in TEUs (Twenty-foot Equivalent Units), would be significant, potentially exceeding several thousand. The precise dimensions would depend on the specific vessel.

-

Vessel Type: Depending on the specific Hyundai 650, it could be classified as Panamax or Post-Panamax. Panamax ships are sized to transit the Panama Canal, while Post-Panamax vessels are larger.

-

Unique Features: Modern cargo ships often incorporate advanced technologies to improve efficiency and safety. These might include:

- Fuel-efficient engines: Reducing emissions and operational costs.

- Advanced navigation systems: Enhancing precision and safety at sea.

- Optimized hull designs: Minimizing drag and maximizing fuel economy.

-

Key Statistics (Example):

- Cargo Capacity: Approximately 4,000 TEUs (This is an example; the actual capacity varies)

- Cruising Speed: Around 20 knots (This is an example; the actual speed varies)

- Typical Journey Duration: Varies greatly depending on origin and destination, but could range from several weeks to a month or more.

<h2>The Ulsan Auto Factory: Hyundai's Production Hub</h2>

The Ulsan Auto Factory is Hyundai's flagship manufacturing facility and one of the largest car manufacturing plants globally. Its scale and efficiency are critical to Hyundai's success in the competitive automotive market.

-

Production Capacity: The factory boasts an enormous annual production capacity, producing millions of vehicles across various models.

-

Key Vehicle Models: A wide array of Hyundai vehicles are manufactured here, including popular sedans, SUVs, and potentially even commercial vehicles. Specific models would vary over time.

-

Logistical Needs: The sheer volume of production necessitates a highly efficient supply chain. Just-in-time (JIT) manufacturing practices mean that components must arrive precisely when needed, highlighting the critical role of timely maritime transport. Any delay in shipping can have a significant ripple effect across the entire production line.

-

Bullet Points:

- Annual Vehicle Production: Millions of units annually (exact figures vary year to year).

- Key Models Manufactured: (Specific models should be listed based on current production – research required).

- Importance of JIT: Minimal inventory on-site; reliance on precise delivery schedules to maintain production.

<h2>The Voyage: From Origin to Ulsan</h2>

The Hyundai 650's journey to Ulsan begins at various origin ports worldwide. These ports could be located in countries supplying automotive components, reflecting Hyundai's globally dispersed supply chain.

-

Typical Route: The route varies based on the origin port, but generally involves traversing major shipping lanes, potentially passing through the Suez Canal or other significant waterways.

-

Challenges Faced: Maritime transport presents numerous challenges, including:

- Weather conditions: Storms, high seas, and unpredictable weather patterns can cause delays.

- Canal transit: Navigating busy canals like the Suez Canal requires precise timing and coordination.

- Port congestion: Delays at ports of call due to high traffic can impact delivery schedules.

-

Precise Navigation and Timing: Precise GPS tracking and adherence to strict delivery schedules are paramount to maintain the efficiency of the Ulsan plant's JIT system.

-

Bullet Points:

- Possible Origin Ports: Various locations across Asia, Europe, and North America (research required for specifics).

- Key Navigational Points: Suez Canal, Strait of Malacca, etc. (route varies depending on origin).

- Potential Logistical Hurdles: Port congestion, severe weather, unforeseen mechanical issues.

<h3>The Role of Logistics and Supply Chain Management</h3>

Effective logistics are the backbone of the Hyundai 650's successful journey and the smooth operation of the Ulsan factory. Without efficient management of this process, Hyundai's production would be significantly hampered.

-

Real-time Tracking: Modern technology allows for real-time tracking of the Hyundai 650's progress, enabling proactive adjustments to potential delays.

-

Freight Forwarders and Customs Brokers: Specialized companies handle the complex paperwork and regulations associated with international shipping, ensuring smooth customs clearance.

-

Supply Chain Optimization: Constant efforts are made to streamline the entire supply chain, from sourcing components to delivery, to maximize efficiency and minimize costs. This includes identifying and mitigating potential bottlenecks.

-

Bullet Points:

- Real-time Tracking Systems: GPS, satellite tracking, and specialized software.

- Role of Freight Forwarders: Handling documentation, arranging transport, and managing logistics across different modes of transportation.

- Importance of Supply Chain Optimization: Reducing lead times, minimizing inventory, and enhancing overall efficiency.

<h2>Conclusion</h2>

The journey of the Hyundai 650 cargo ship to the Ulsan Auto Factory is a compelling example of the complex and vital role of maritime transport in the global automotive industry. Efficient logistics and effective supply chain management are paramount for manufacturers like Hyundai. The Hyundai 650's reliable delivery of essential components ensures the uninterrupted operation of the Ulsan plant, contributing significantly to the production of millions of vehicles each year. To learn more about the fascinating world of maritime logistics and its impact on global automotive production, continue your exploration. Dive deeper into the world of Hyundai 650 cargo ship journeys and the innovative solutions driving efficient automotive transportation!

Featured Posts

-

Understanding The Big Rig Rock Report 3 12 A Rock 101 Guide

May 23, 2025

Understanding The Big Rig Rock Report 3 12 A Rock 101 Guide

May 23, 2025 -

Recent Surge In Us China Trade Understanding The Trends

May 23, 2025

Recent Surge In Us China Trade Understanding The Trends

May 23, 2025 -

Vybz Kartel Self Esteem Issues And Skin Bleaching

May 23, 2025

Vybz Kartel Self Esteem Issues And Skin Bleaching

May 23, 2025 -

Hulu Movies Leaving Soon Dont Miss These Before They Re Gone

May 23, 2025

Hulu Movies Leaving Soon Dont Miss These Before They Re Gone

May 23, 2025 -

Thlyl Ser Aldhhb Fy Qtr Alywm Alithnyn 24 Mars

May 23, 2025

Thlyl Ser Aldhhb Fy Qtr Alywm Alithnyn 24 Mars

May 23, 2025

Latest Posts

-

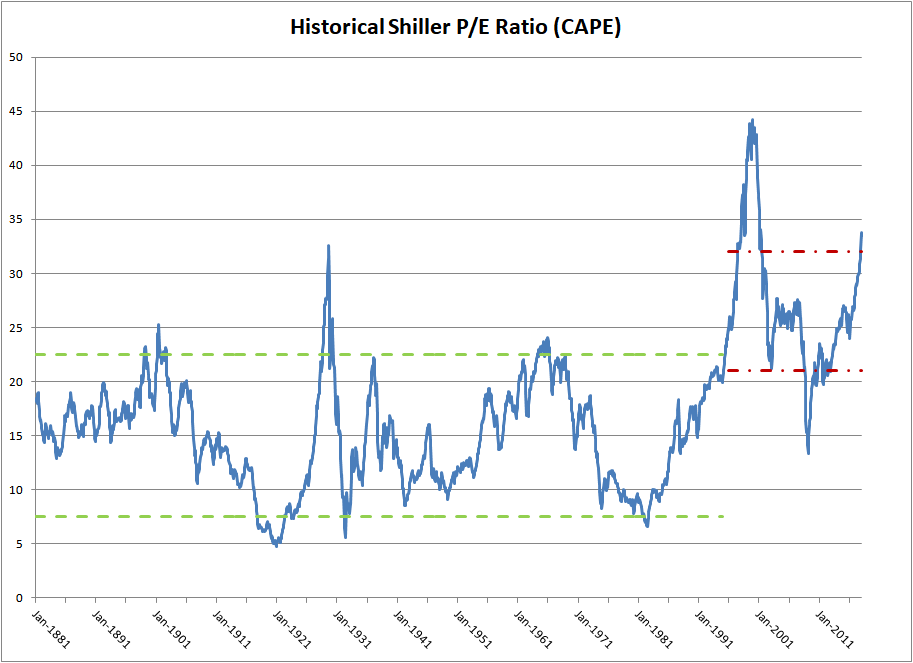

Why Investors Shouldnt Worry About Elevated Stock Market Valuations Bof A

May 23, 2025

Why Investors Shouldnt Worry About Elevated Stock Market Valuations Bof A

May 23, 2025 -

Are High Stock Valuations Justified Bof As Take For Investors

May 23, 2025

Are High Stock Valuations Justified Bof As Take For Investors

May 23, 2025 -

Understanding The Controversy Surrounding Thames Water Executive Bonuses

May 23, 2025

Understanding The Controversy Surrounding Thames Water Executive Bonuses

May 23, 2025 -

The Thames Water Executive Bonus Debate A Critical Analysis

May 23, 2025

The Thames Water Executive Bonus Debate A Critical Analysis

May 23, 2025 -

Bof As Reassurance Are High Stock Market Valuations Really A Worry

May 23, 2025

Bof As Reassurance Are High Stock Market Valuations Really A Worry

May 23, 2025